The evaluation of biogas plants must include consideration not only of the monetary cost/ benefit

factors, but also of the ascertainable nonpecuniary and unquantifiable factors. Time and again,

practical extension work with the owners of small and medium-sized farms shows that a purely

monetary approach does not reflect the farmers' real situation. For a farmer who thinks and works in

terms of natural economic cycles, knowing how many hours of work he stands to save is often more

important than knowing how much money he stands to gain. A similar view is usually taken of the

often doubtful monetary evaluation of such a plant's qualitative and socioeconomic impact.

Figure 8.1 surveys the essential parts of an economic analysis. In practice, however, the collecting

of information and data can present problems: experience shows, for example, that an exact

breakdown of cost and benefits can hardly be arrived at until the plant has been in service long

enough for the user to have gained some initial experience with its operation. Economic prognoses

therefore should give due regard to such limitations by including calculations for various scenarios

based on pessimistic, average-case and optimistic assumptions. Consequently, the data stated in

the following calculations and considerations are intended to serve only as reference values. Any

attempt to convert local plant & equipment costs into DM-values is seriously complicated by the fact

that exchange rates are often set more or less arbitrarily and that the figures used may derive from

unstable black-market prices.

8.2 Working-time balance

For the users of family-size plants - primarily the operators of small to medium-size farms - the

following three elements of the biogas plant evaluation have the most relevance:

- working-time balance

- micro-economic analysis and

- socioeconomic and qualitative considerations.

Working-time balancing is most important when the farm is, at most, loosely involved in cash-crop

markets, so that the cost/benefit factors are more likely to be reflected in terms of hours worked, as

in money.

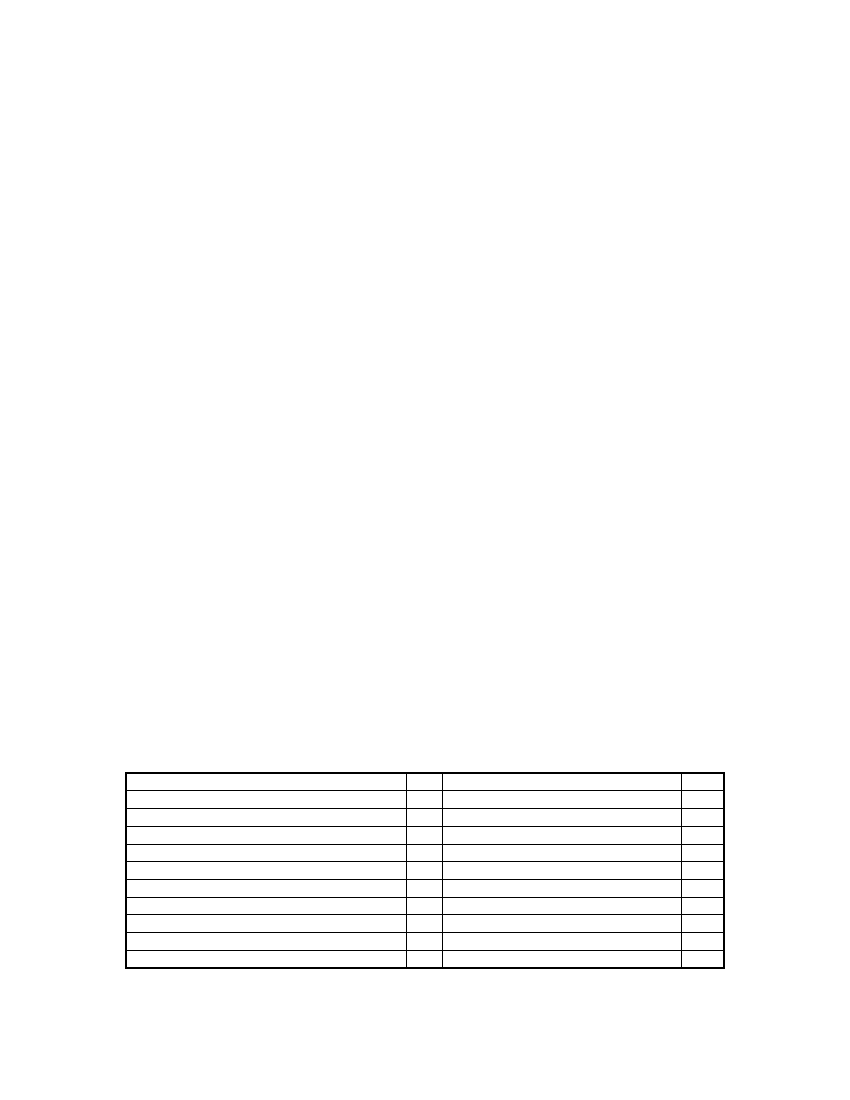

Table 8.1 exemplifies a comparison of time expenditures for a farm with a biogas plant and for a

similar one without a biogas plant. The unit of calculation is hours worked per year (h/a) by the

farmer and his family. Any expenses for external assistance, e.g. "hired hands", appear only in the

monetary (cashflow) calculation (cf. chapter 8.3).

Table 8.1: Comparison of working time with and without biogas utilization (Source:

OEKOTOP)

Working time with biogas plant

h/a Working time without biogas plant

Planning/know-how acquisition

..... Mucking out the stables

Plant construction and installation of appliances

Hauling off/disposal of organic wastes

..... Collecting, hauling and preparing fuel

Feeding/collecting manure

..... Cooking

Fetching water

..... Cleaning and repair of fireplace

Cooking

..... Spreading of NPK-fertilizer

Maintenance and repair work

..... Tending of animals

Spreading of digested slurry/fertilizing

.....

Tending of animals

.....

Total

..... Total

h/a

.....

.....

.....

.....

.....

.....

.....

.....

96