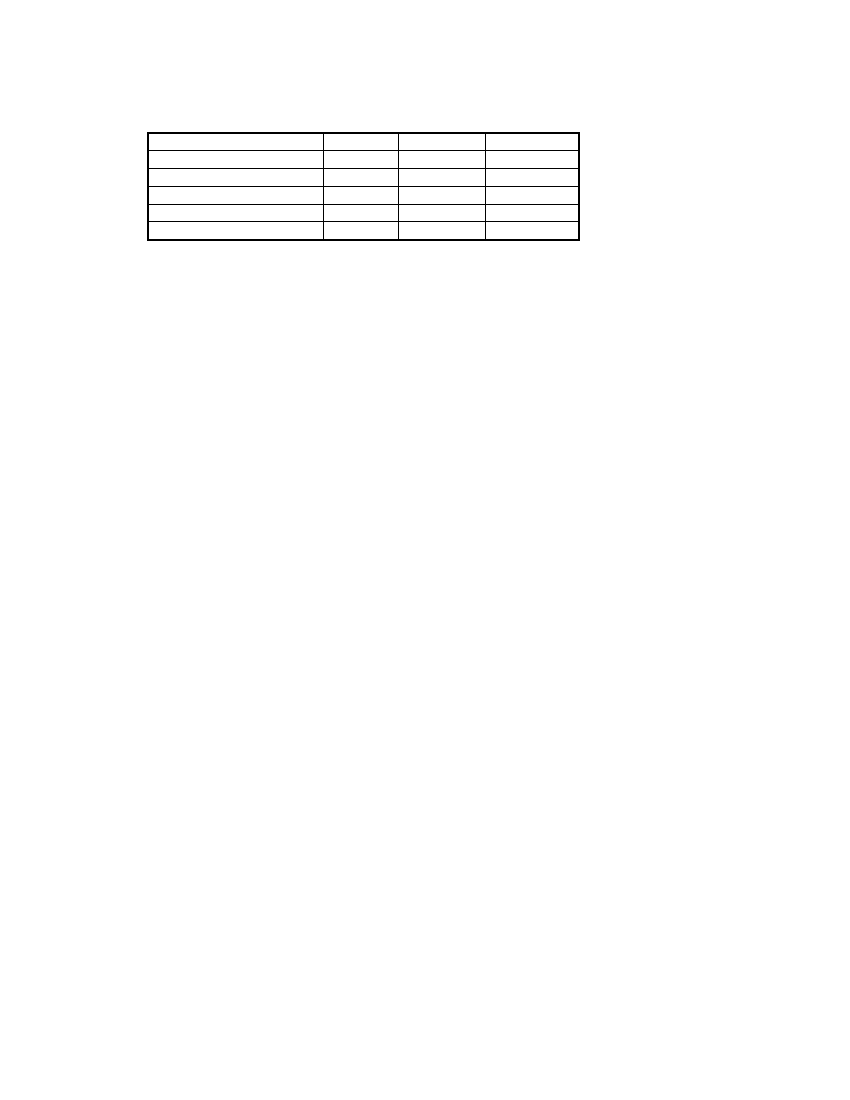

Table 6.3: Slaughterhouse waste quantities (Source: OEKOTOP)

Type of waste

Stomach contents

Intestinal contents

Blood

Offal

Dung (without fodder)

Cattle

11.6%¹

3.3%¹

~14 kg

2-5 kg

5 kg

Sheep

4.3%¹

~2 kg

0.5-1 kg

0.8 kg

Pigs

2.8%¹

~4 kg

1-1.5 kg

1.5 kg

¹ Expressed as percentages of live weight

7. Plant operation, maintenance and repair

The main objective of any plant owner/user is to have a well-functioning biogas plant that involves a

modest amount of work for operating it and requires very little effort and expense for maintenance

and repair in the long run. Smooth running of a biogas plant is dependent on good information and

careful planning and construction. Operating errors and false expectations are the most frequent

causes of plant outage.

7.1 Commissioning of biogas plants

The commissioning procedure for a biogas plant includes:

- inspection and final acceptance of all components

- initial filling

- starting the plant

- user familiarization

Inspection and final acceptance

Prior to filing the plant, all components must be carefully inspected for proper function and suitability

for acceptance. Of particular importance at the time of final acceptance is seal testing of the

digester, gasholder and gas pipes.

It must be kept in mind that the seal tests described below are very laborious without pumps (e.g.

hauling of more than 10 m³ water) and may not even be feasible if water is scarce, in which case

such testing must be dispensed with. The time and effort involved must be weighed against the risk

of having to empty the plant after completely filling it with slurry. In either case, it is very advisable to

use a motor pump.

Water-seal testing

Fill the entire digester with water and check the fill level in all components.

Once all components have become saturated with water (after about 1 day), refill to the zero line,

wait one day, and then remeasure. If the water loss amounts to less than 2% of the digester

volume, the plant may be regarded as leaktight.

Seal testing (water and gas) of a fixed-dome plant

Fixed-dome plants are regarded as leaktight if the water-seal test shows less than 2% water loss,

and the gas-seal test shows less than 5% gas loss.

87