Table 5.14: Composition and properties of biogas, and its constituents under s.t.p.

conditions (0 °C, 1013 mbar)

(Source: OEKOTOP, compiled from various sources)

Constituents and properties

Volume fraction (%)

Net calorific value (kWh/m³)

Ignition threshold (% in air)

Ignition temperature (°C)

Crit.pressure (bar)

Crit. temp. (°C)

Normal density (g/1)

Gas/air-density ratio

Wobbe index, K (kWh/m³)

Spec. heat, cp (kI/m³ °C)

Flame propagation (cm/s)

CH4

CO2

55-70

9.9

5-1S

650-750

47

-82.5

0.72

0.55

13.4

1.6

43

27-44

-

-

-

75

31.0

1.98

2.5

-

1.6

-

H2 H2S

1

3.0

4-80

585

13

-240

0.09

0.07

-

1.3

47

3

6.3

4-45

-

89

100.0

1.54

1.2

-

1.4

-

60% CH4/

40% CO2

100

6.0

6-12

650-750

75-89

-82.5

1.2

0.83

6.59

1.6

36

65% CH4/

34%

C02/

1% rest

100

6.8

7.7 - 23

650-750

75-89

-82.5

1.15

0.91

7.15

1.6

38

Reduction of the hydrogen-sulfide content (H2S) may be necessary if the biogas is found to contain

an excessive amount, i.e. more than 2%, and is to be used for fueling an engine. Since, however,

most biogas contains less than 1% H2S, desulfurization is normally unnecessary, especially if it is

to be used for operating a stationary engine.

For small-to-midsize systems, desulfurization can be effected by absorption onto ferric hydrate (Fe

(OEI)3), also referred to as bog iron, a porous form of limonite. The porous, granular purifying mass

can be regenerated by exposure to air.

The absorptive capacity of the purifying mass depends on its iron-hydrate content: bog iron

containing 5-10% Fe(OH)3 can absorb about 15 g sulfur per kg without being regenerated and

approximately 150 g/ kg through repetitive regeneration. It is a very noteworthy fact that many types

of tropical soil (laterites) are naturally ferriferous and, hence, suitable for use as purifying mass.

Reduction of the carbon-dioxide content (CO2) is very complicated and expensive. In principle, CO2

can be removed by absorption onto lime milk, but that practice produces "seas" of lime paste and

must therefore be ruled out, particularly in connection with large-scale plants, for which only high-

tech processes like microscreening are worthy of consideration. CO2 "scrubbing" is rarely

advisable, except in order to increase the individual bottling capacity for high-pressure storage.

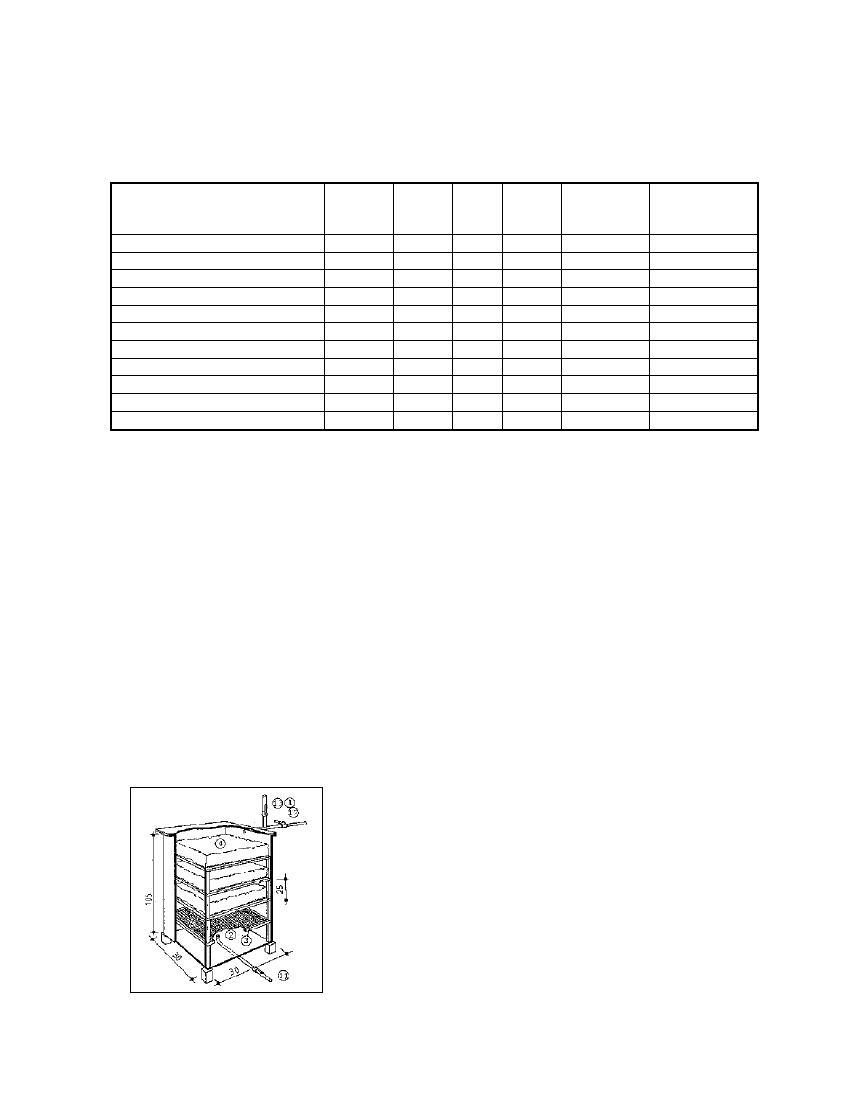

Fig. 5.29: Ferric-hydrate gas purifier. 1 Gas pipe, 11 Raw-gas

feed pipe, 12 Clean-gas discharge pipe, 13 Purging line, 2 Metal

gas purifier, 3 Shelves for purifying mass, 4 Purifying mass

(Source: Muche 1984)

66