6. Large-scale biogas plants

Biogas technology, or better: anaerobic-process engineering, Is becoming increasingly important as

a means of treating and cleaning industrial organic waste materials and highly loaded organic

wastewater.

This applies in particular to the following ranges of production:

- large-scale stock farming

- industrial processing of agricultural produce (refining of sugar, production of starch, winning of

fibers, processing of coffee, generation of alcohol, slaughterhouses, etc.)

- industrial and urban refuse and sewage (manufacturing of paper, organic household waste,

sewage sludge, biotechnological industries).

Most biogas plants used in those areas are large-scale plant systems with volumes ranging from

several hundred to several thousand cubic meters.

Compared to aerobic treatment, anaerobic processes offer comparable performance with regard to

purification capacity and conversion rates, but also stand apart from the former in that they:

- require less energy to keep the process going and to generate useful energy in the form of

biogas, and

- produce less organic sludge, because the growth rate of anaerobic microorganisms is slower

than that of aerobic microorganisms.

Consequently, anaerobic treatment of waste materials and wastewater offer some major

advantages for a comparable initial invest" meet. Nonetheless, much of the technology has not yet

passed the testing stage.

Due to the size of plant, different objectives and special requirements concerning operation and

substrates, the anaerobic treatment of waste materials and wastewater involves a different set of

planning mechanisms, plant types and implementational factors. To go into detail on this subject

would surpass the intended scope of this manual; besides, extension officers hardly need expect to

be confronted with the job of planning such plants. Nevertheless, some basic information is offered

here to give the reader a general grasp of what large-scale biogas technology involves.

In discussing the various waste-treatment options, differentiation is made between wastewater

(organic - highly loaded) and waste materials/residues (organic solids).

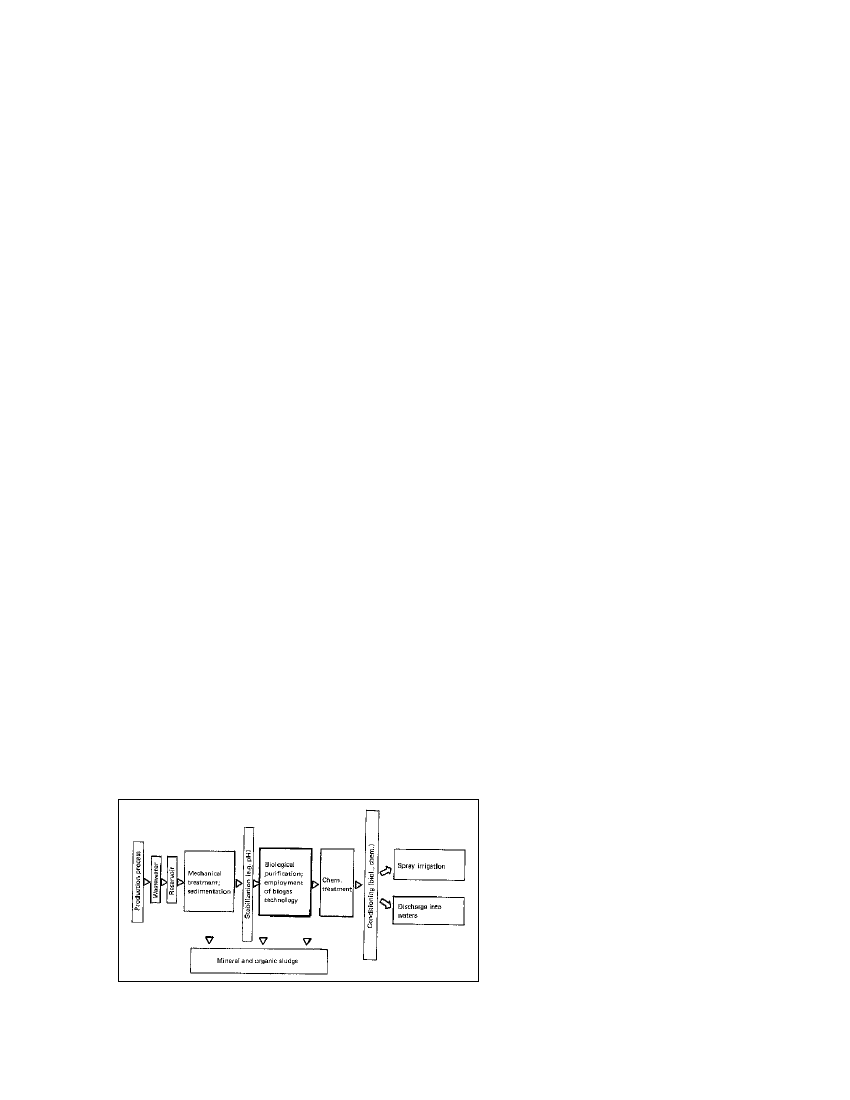

Fig. 6.1: Basic principle of organic

wastewater treatment (Source:

OEKOTOP)

82