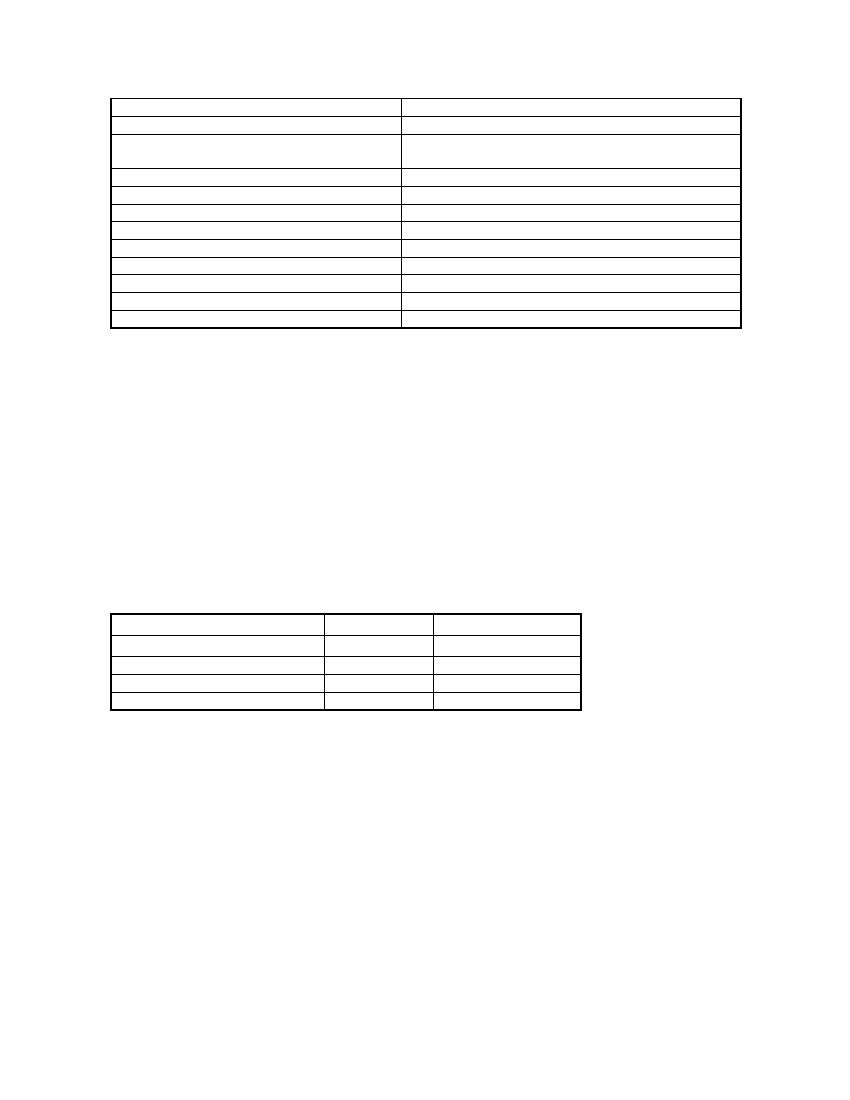

Luminous efficiency (Re) light power

referred to the energy input (Ei)

Measured values:

Illuminance

E=901x

meas. distance, r = 1.0 m

gas consumption, V = 110 1/h

cal. value, n.c.v. = 6 kWh/m³

photoelectric cell

V = biogas consumption n.c.v. = net calorific value

Re = F/Ei (lm/kW)

Sample calculation

Results:

Luminous intensity

I = E x r² = 90 cd

luminous flux

F = I x w = 90 x 6.28 = 565 lm

luminous efficiency

Re = F:Q = 565:110 = 5.1 lm/lxh

Re = F/Ei = 565:660 = 0.9 lm/W

Practical experience shows that commercial type biogas lamps are not optimally designed for the

specific conditions of biogas combustion (fluctuating or low pressure, varying gas composition). The

most frequently observed shortcomings are:

- excessively large nozzle cross sections

- excessively large gas mantles

- no possibility of changing the injector

- poor or lacking means of combustion-air control.

Such drawbacks result in unnecessarily high gas consumption and poor lighting. While the

expert/extension officer has practically no influence on how a givenlamp is designed, he can at least

give due consideration to the aforementioned aspects when it comes to selecting a particular

model.

Table 5.20: Comparison of various biogas lamps (Source: Biogas Extension Program)

Type of lamp

D 80 - 3 Juojiang/PR China

Avandela - Jackwal/Brazil

Patel Outdoor-single/India

Camping-Gas

Suitability1

o2

+

++

+

Gas consumption

?

100 l/h

150 l/h

?

1 Quality criteria: gas consumption, brightness, control

2 Quality ratings: ++ very good, + good, o average

Biogas lamps are controlled by adjusting the supply of gas and primary air. The aim is to make the

gas mantle burn with uniform brightness and a steady, sputtering murmer (sound of burning, flowing

biogas). To check the criteria, place the glass on the lamp and wait 2 - 5 minutes, until the lamp has

reached its normal operating temperature. The lamps compared in table 5.20 operate at a gas

pressure of 5 - 15 cmWG. If the pressure is any lower, the mantle will not glow, and if the pressure

is too high (fixed-dome systems) the mantle may tear.

Adjusting a biogas lamp requires two consecutive steps:

1. precontrol of the supply of biogas and primary air without the mantle, initially resulting in an

elongated flame with a long inner core;

71