Table 5.23: Engine-conversion requirements for various duty and control modes (Source:

Mitzlaff 1986)

Duty mode

Speed: constant power:

constant e.g. for a pump with

constant head and constant

delivery

Speed: constant power:

variable e.g. for a constant-

frequency subject to varying

power; or for a pump with

constant head and varying

delivery volume

Speed: variable power:

variable e.g. for powering

various types of machines

Control mode

Diesel or spark- ignition

engine: fixed manual

adjustment, no readjustment

necessary under normal

circumstances

Automatic speed control:

Spark-ignition: electronic

governor controls the throttle

Diesel: fixed biogas fraction,

with speed control via diesel

intake governor

Spark-ignition: by hand (if

varying speed is acceptable)

or electric with setpoint

control Diesel: by hand via

accelerator Iever

Conversion mode

addition of a simple, manually

adjusted mixing chamber

Spark-ignition: carburetor or gas

mixing valve with throttle; elec

tronic control Diesel: Regulator and

hand-adjusted mixing chamber

Spark-ignition: electronic with set

point control, gas mixing valve or

carburetor with throttle, plus regu

lator Diesel: simple, hand-adjusted

mixing chamber

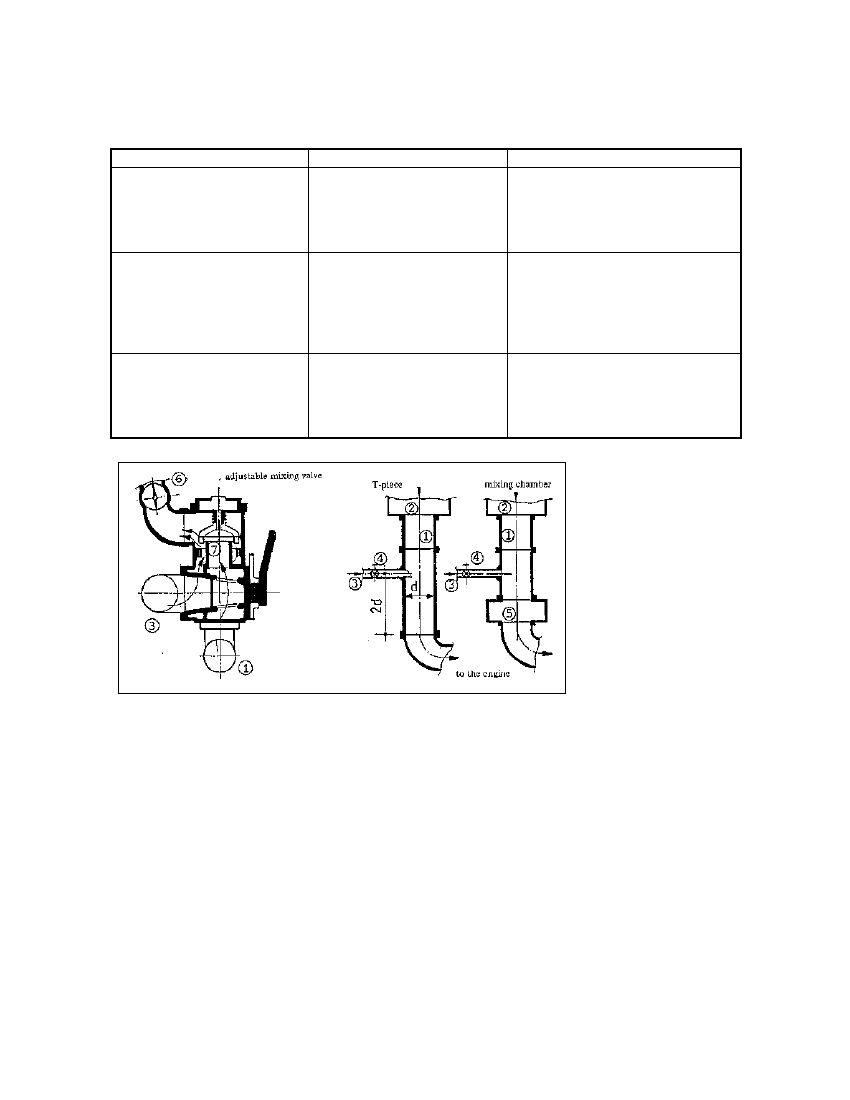

Fig. 5.35: Various gas

mixers for spark-ignition

and diesel engines. 1 Air

intake, 2 Air filter, 3

Biogas supply pipe, 4

Biogas control valve, 5

Mixing chamber (0.5 - 1

X piston displacement) 6

Throttle, 7 Mixing valve

(Source: OEKOTOP)

Converting a spark-ignition engine results in a loss of performance amounting to as much as 3070.

While partial compensation can be achieved by raising the compression ratio to E = 11-12, such a

measure also in,creases the mechanical and thermal load on the engine.

Spark-ignition engines that are not expressly marketed as suitable for running on gas or unleaded

gasoline may suffer added wear & tear due to the absence of lead lubrication.

The speed control of converted spark-ignition engines is effected by way of a hand-operated

throttle. Automatic speed control for different load conditions requires the addition of an electronic

control device for the throttle.

77