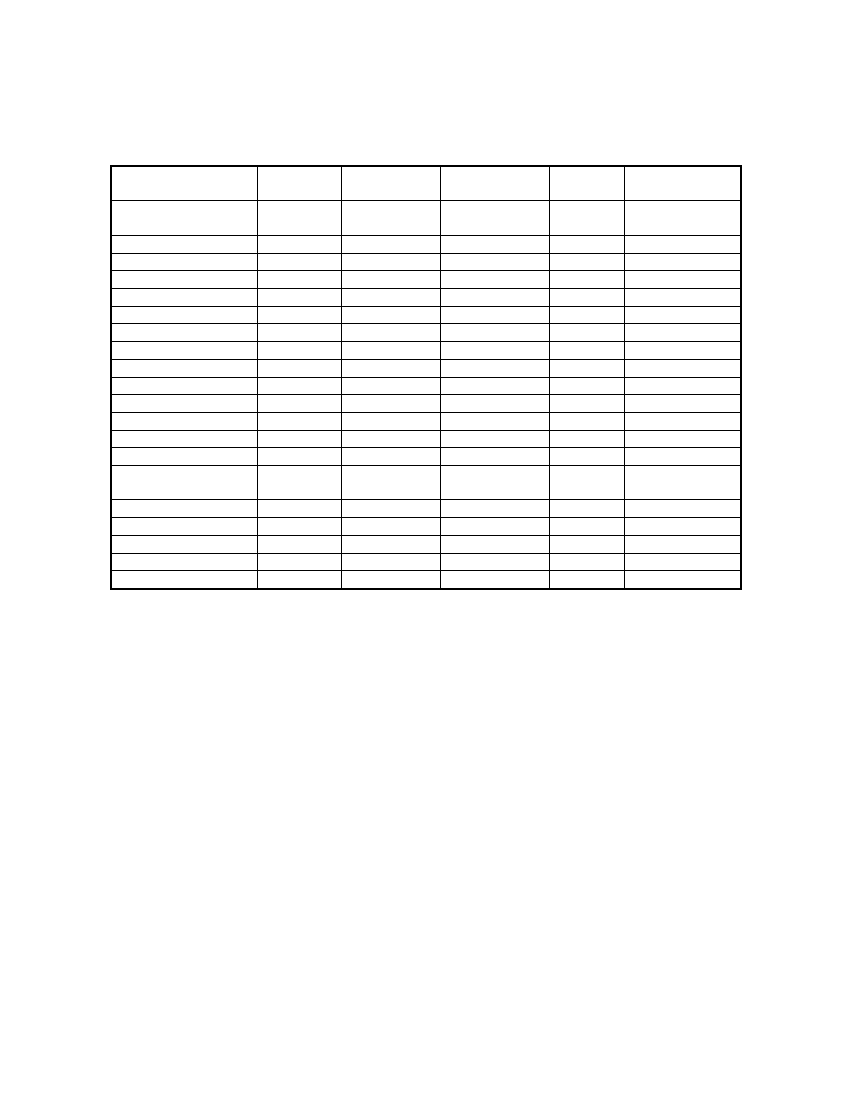

Table 6.1: Some examples of biogas production from agro-industrial residues and

wastewater

(Source: OEKOTOP, compiled from various sources)

Area of production

Slaughterhouse

Fruit and vegetables

Olive-oil extraction

Whey

Potato starch

Yeast factory

Sugar mill

Milk processing

Molasses slop

Molasses distillery

Brewery

Tannery

Pharmaceut.ind.

Refuse + sewage

sludge

Refuse

Cattle farming

Pig farming

Poultry farming

Sewage sludge

Retention

time

[d]

0.5- 8.5

32.0

20.0-25.0

2.0-5.0

-

0.5-0.7

0.2-1.0

3.4-7.4

10.0

1.2-3.5

2.3-10.0

0.5

0.5-2.0

11.0-22.5

Digester

loading

[kg/m³ X d]

1.2-3.5 COD

0.8-1.6 VS

1.2-1.5 TS

6.4 BOD

7.5 COD

1.0-8.0 COD

12.0-16.5 COD

0.7-2.0 VS

3.9 VS

18.3 COD

1.8-5.5 TS

2.7-31.9 COD

0.2-3.5 COD

1.2-3.1 VS

Gas production

[m³/kg]

0.3-0.5 COD

0.3-0.6 VS

0.7 BOD

0.9 BOD

0.3-0.4 COD

-

-

0.1-0.4 VS

0.9 VS

0.6 COD

0.3 - 0.4 TS

-

0.6 COD

1.0 VS

[m³/m³ X

d]

0.1 - 2.4

-

-

5.5

-

0.5-4

-

-

3.5

6.6

-

-

0.1-2.5

-

Degradation rate

[%]

80 COD

-

80-85 BOD

92 BOD

90-95 BOD

60-70 COD

87-97 COD

86-99 BOD

97 BOD

45-65 COD

-

80-91 COD

94-98 COD

-

25.0-30.0

15.0-35.0

10.0-25.0

15.0-35.0

20.0-30.0

0.7-3.2 VS

0.5-2.5 VS

0.8-4.1 VS

0.6-3.6 VS

1.2-4.5 VS

0.1-0.4 VS

0.2-0.4 VS

0.1-0.5 VS

0.2-0.5 VS

0.1-0.6VS

-

0.6-1.4

0.8-2.1

0.7-1.8

0.8-1.5

-

-

-

-

-

Wastewater treatment

Organically contaminated wastewater contains mostly dissolved substances that are measured in

terms of COD (chemical oxygen demand) and BOD (biochemical oxygen demand, i.e. oxygen

required for mineralizing the organic contents).

The main purpose of wastewater treatment is to remove or mineralize the organic substances, i.e.

to prepare them for release into a receiving body of water or the agricultural environment.

Anaerobic fermentation serves as the biological purifying process. Purification performance rates of

up to 95% BOD are achievable. The choice of process and the achievable purification performance

rates are determined by the type and composition of the substrate/wastewater. In general, dissolved

organic substances are readily biodegradable. Retention times ranging from a few hours to a few

days are not uncommon. On the other hand, some organic substances are hard to break down

(paints, aromates, etc.), while others are toxic and/o,r capable of causing a shortage of nutrients

and adverse medium characteristics (e.g. pH-shifts). A number of special-purpose processes have

been developed for use in anaerobic wastewater treatment in order to compensate for the high

hydraulic loads and lack of bacterial colonization areas:

83