2. fine adjustment with the incandescent body in place, resulting in a brightly glowing incandescent

body, coupled with slight further adjustment of the air supply (usually more).

The adjustment is at its best when the dark portions of the incandescent body have just

disappeared. A luxmeter can be used for objective control of the lamp adjustment.

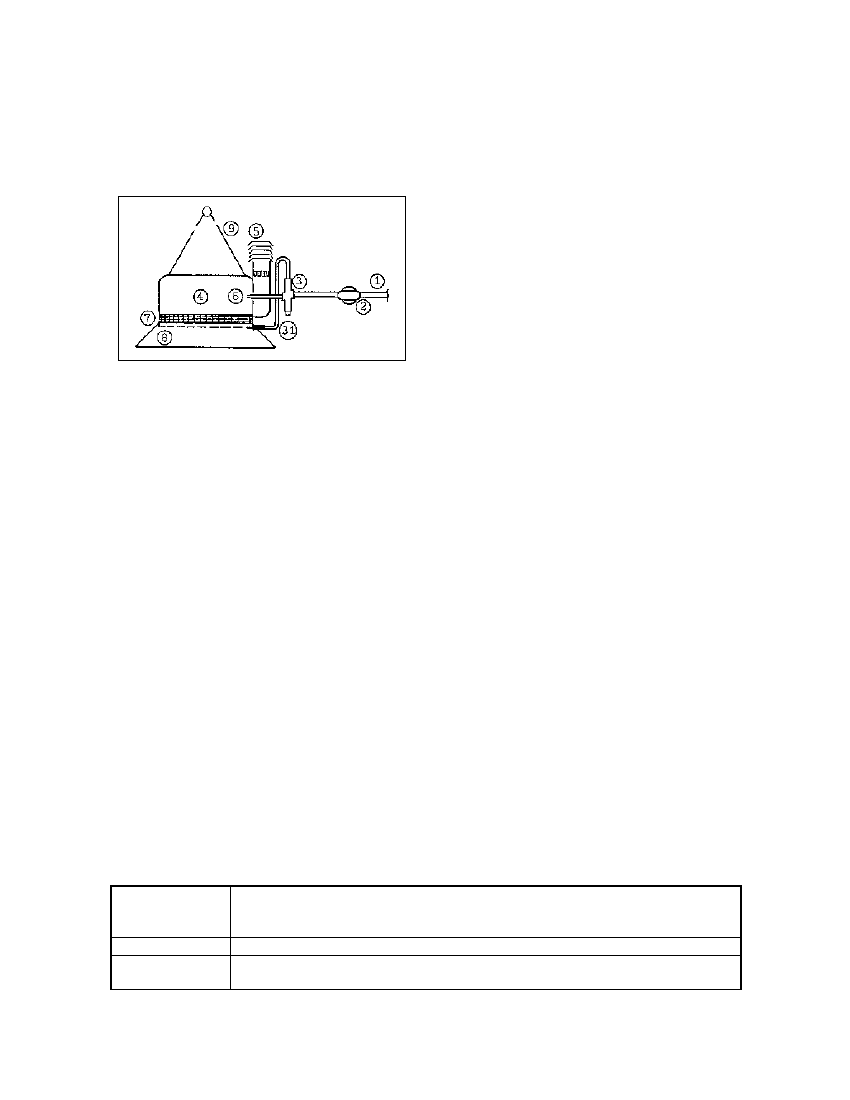

Fig. 5.33: Schematic drawing of a radiant heater. 1

Gas pipe, 2 Shutoff valve, 3 Safety pilot, 31 Heat

sensor, 4 Mixing chamber, 5 Air supply, 6 Injector,

7 Ceramic panel with protective screen, 8

Reflector, 9 Hanger (Source: OEKOTOP / SBM)

Radiant heaters

Infrared heaters are used in agriculture for achieving the. temperatures required for raising young

stock, e.g. piglets and chicks, in a limited amount of space. The nursery temperature for piglets

begins at 30-35 °C for the first week and than gradually drops off to an ambient temperature of 18-

23 °C in the 4th/5th week. As a rule, temperature control consists of raising or lowering the heater.

Good ventilation is important in the stable/nursery in order to avoid excessive concentrations of CO

or CO2. Consequently, the animals must be kept under regular supervision, and the temperature

must be checked at regular intervals.

Radiant heaters develop their infrared thermal radiation via a ceramic body that is heated to 600-

800 °C (red-hot) by the biogas flame.

The heating capacity of the radiant heater is defined by multiplying the gas flow by its net calorific

value (E = Q x n.v.c.), since 95% of the biogas' energy content is converted to heat. Small-heater

outputs range from 1.5 to 10 kW thermal power.

Commercial-type heaters are designed for operating on butane, propane and natural gas at a

supply pressure of between 30 and 80 mbar. Since the primary air supply is. factory-set, converting

a heater for biogas fueling normally consists of replacing the injector; experience shows that biogas

heaters rarely work satisfactorily because the biogas has a low net calorific value and the gas

supply pressure is below 20 mbar, in which case the ceramic panel is not adequately heated, i.e.

the flame does not reach the entire surface, and the heater is very susceptible to draft.

Biogas-fueled radiant heaters should always be equipped with a safety pilot, and an air filter is

required for sustained operation in dusty barns.

Table 5.21: Artificial brooding requirements, exemplified for a chick incubator (Source:

Wesenberg 1985)

Incubation heat

Hatching time:

Relative

humidity:

37.8 °C at the beginning, declining to 30.0 °C at the end of the incubation

period. The temperature should be kept as constant as possible. Any

temperature in excess of 39 °c can damage the eggs.

approximately 21 days

60-90 %

72