Table 4.3 lists simplified gas-yield values for cattle and pigs. A more accurate estimate can be

arrived at by combining the gas-yield values from, say, table 3.5 with the correction factors for

digester temperature and retention time shown in figure 5.2.

GYT,RT = mGy x fT,RT

GYT,RT = gas yield as a function of digester temperature and retention time

mGy = average specific gas yield, e.g. 1/kg VS (table 3.5)

fT,RT = multiplier for the gas yield as a function of digester temperature and retention time (cf. fig.

5.2)

As a rule, it is advisable to calculate according to several different methods, since the available

basic data are usually very imprecise, so that a higher degree of sizing certainty can be achieved by

comparing and averaging the results.

Establishing the plant parameters

The degree of safe-sizing certainty can be increased by defining a number of plant parameters:

Specific gas production (Gp)

i.e. the daily gas-generation rate per m³ digester volume (Vd), is calculated according to the

following equation:

Gp = G: Vd (m³ gas/m³ Vd x d)

Digester loading (Ld)

Ld - TS (VS) input/m³ digester volume (kg TS (VS)/m³ Vd x d)

Then, a calculated parameter should be checked against data from comparable plants in the region

or from pertinent literature.

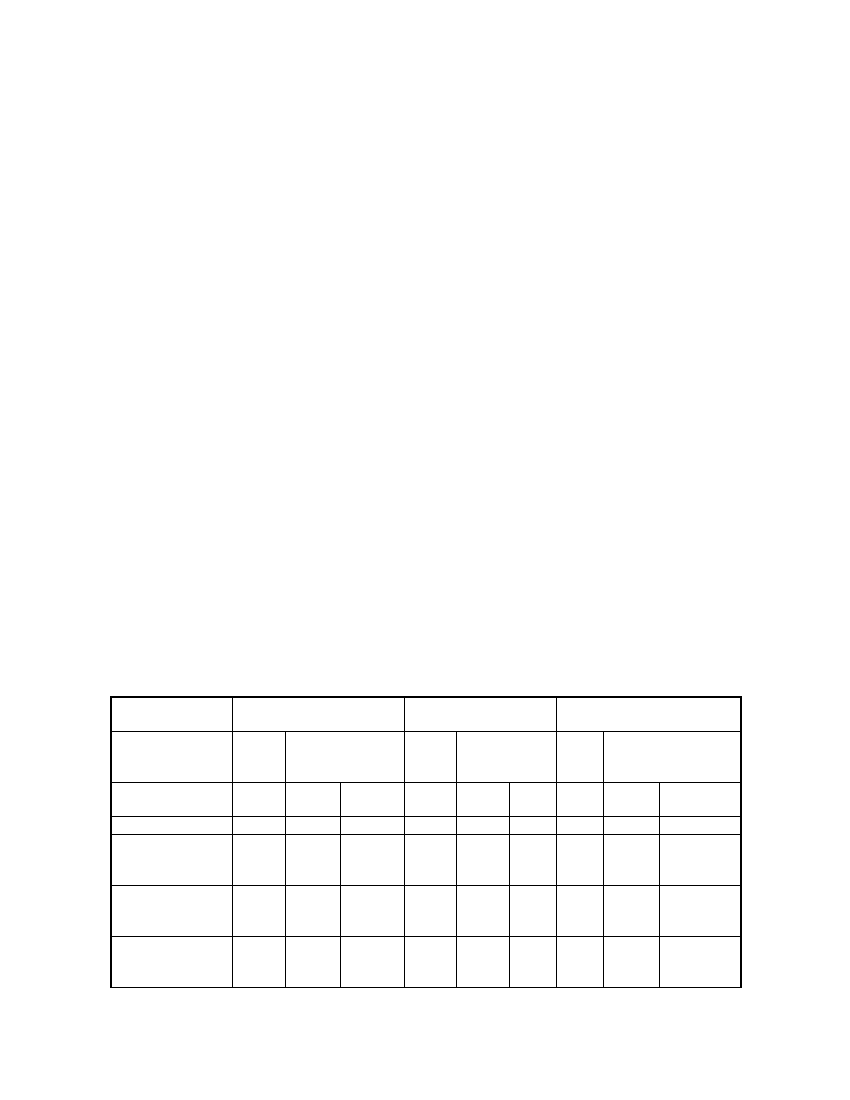

Table 4.3: Simplified gas-yield values for substrate from cattle and pigs (digesting

temperature: 22-27 °C) (Source: OEKOTOP)

Type of housing/

manure

24-h stabling

- dung only

(moist),unpaved

floor (10% losses)

- dung and

urine,concrete

floor

- stable manure

(dung + 2 kg litter),

concrete floor

Cattle, live wt. 200 - 300

kg

manu Gas yield (I/d)

re

yield

(kg/d) RT=60 RT=80

9-13

300-

450

20-30 350-

510

22-32 450-

630

350-500

450-610

530-730

Buffalo, live wt. 300 -

450 kg

manu Gas yield

re (I/d)

yield

(kg/d) RT=60 RRT

=80

14-18 450-

540

300-

620

30-40 450-

600

5440-

710

32-42 550-

740

630-

890

Pigs, live wt 50 - 60 kg

man

ure

yield

(kg/d

)

Gas yield (l/d)

RT=40 RT=60

--

-

2.5- 120-

3.0 140

--

150-180

-

34