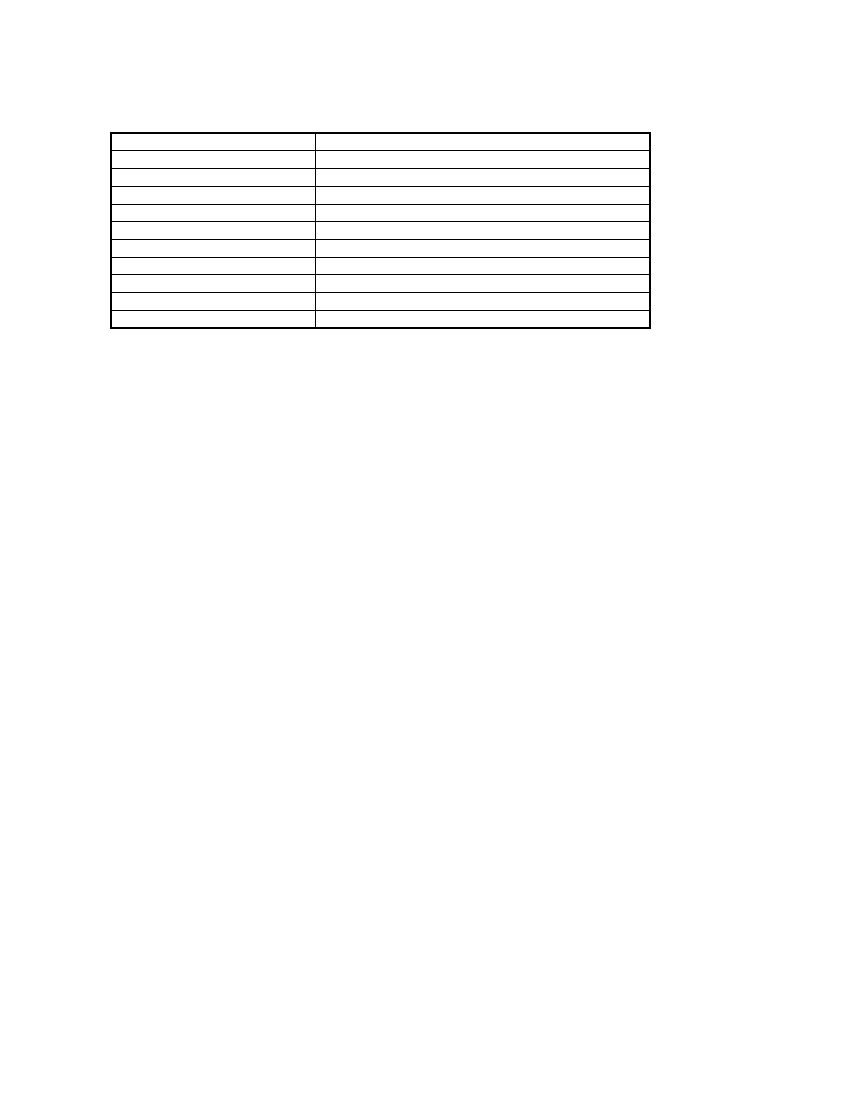

Table 5.22: Technical data of absorption refrigerators (Source: OEKOTOP)

Heating medium

Max. ambient temperature

Heating temperature

Cooling temperature

- refrigerator

- freezer

Efficiency

Gas consumption

Energy-

consumption indices

gas, kerosene, electricity

40ºC

100-150 °C

5 - 10 °C

down to approx. -12 °C

1.5 - 4.0% of the thermal input

a) calculable via the desired refrigeration capacity

b) conversion of factory data via power input

1-4 W/l useful volume

0.3-0.81 biogas/l useful volume X h

5.5.4 Biogas-fueled engines

Basic considerations

The following types of engines are, in principle, well-suited for operating on biogas:

- Four-stroke diesel engines: A diesel engine draws in air and compresses it at a ratio of 17:

1 under a pressure of approximately 30-40 bar and a temperature of about 700 °C. The

injected fuel charge ignites itself. Power output is controlled by varying the injected amount

of fuel, i.e. the air intake remains constant (so-called mixture control).

- Four-stroke spark-ignition engines: A spark-ignition engine (gasoline engine) draws in a

mixture of fuel (gasoline or gas) and the required amount of combustion air. The charge is

ignited by a spark plug at a comparably low compression ratio of between 8: 1 and 12: 1.

Power control is effected by varying the mixture intake via a throttle (so-called charge

control).

Four-stroke diesel and spark-ignition engines are available in standard versions with power ratings

ranging from 1 kW to more than 100 kW. Less suitable for biogas fueling are:

- loop-scavenging 2-stroke engines in which lubrication is achieved by adding oil to the liquid

fuel, and

- large, slow-running (less than 1000 r.p.m.) engines that are not built in large series, since

they are accordingly expensive and require complicated control equipment.

Biogas engines are generally suitable for powering vehicles like tractors and light-duty trucks

(pickups, vans). The fuel is contained in 200-bar steel cylinders (e.g. welding-gas cylinders). The

technical, safety, instrumentational and energetic cost of gas compression, storage and filing is

substantial enough to hinder large-scale application. Consequently, only stationary engines are

discussed below.

Essential terms and definitions

Knowledge of the following terms pertaining to internal combustion engines is requisite to

understanding the context:

74