7.4 Plant repair

Repair measures for biogas plants (cf. table 7.5) are necessary in case of acute malfunctions and

as indicated by routine monitoring. Repair measures exceeding simple maintenance work usually

require outside assistance, since the user himself may not have the necessary tools or know-how.

It is advisable to have the annual maintenance work mentioned in chapter 7.3 performed by

external artisans With prior experience in biogas technology. Such maintenance and repair work

should be ordered on a contract basis. Past project experience shows that professional biogas

repair and maintenance services can be very important for ensuring long-term plant performance.

Such services should include general advice, functional testing, troubleshooting, spare-parts

delivery and the performance of repair work.

Quantity and quality of substrate

- low/less daily input

- excessive dilution with water

Ascertain by control measurements

Gas system leaks

- gasholder

- gas pipe

- valves and fittings

Ascertain by checking all components and connections for leaks with the aid of soapy water

Disturbance of the biological process

Indications:

- heavy odor

- change of color of digested material

- drop in pH

Possible remedial measures:

- inspect the quality of the substrate

- stop biomass until the process returns to normal

- stabilize the pH, e.g. with lime

- add cattle dung or healthy slurry

- investigate the user's filling methods to determine if pollutants or noxious substances

(detergents, pesticides, etc.) are getting into the plant

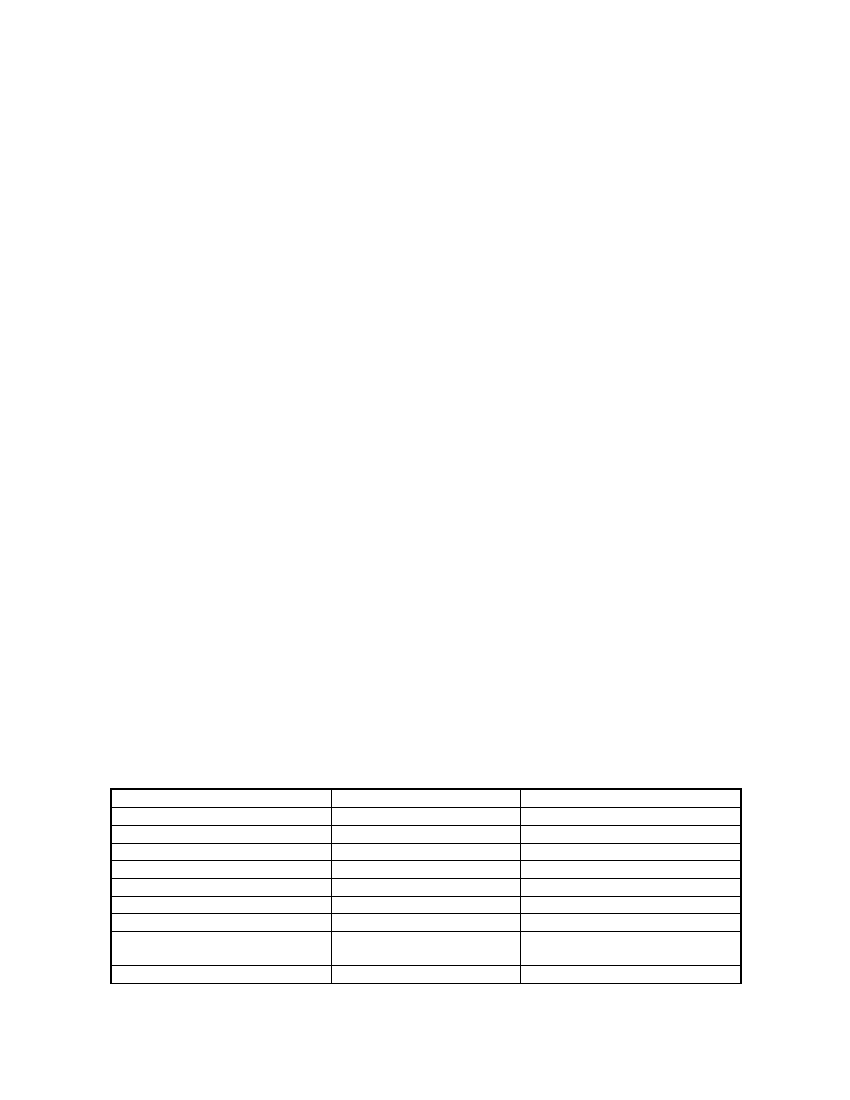

Table 7.4: Simple-plant malfunctions and remedial measures (Source: OEKOTOP)

Problem

Plugged-up inlet pipe

Stuck gasholder

Possible cause

fibrous substrate

floating scum

Tilted gasholder

Low gas production, poor gas quality

Receding slurry level

Inadequate gas storage in fixed-

dome

plants

broken guideframe

cf. table 7.3

leak in plant

leak in gasholder

Countermeasures

use rod to unplug the pipe

1. turn the gasholder

2. take off the gasholder

and remove the scum

repair

cf. table 7.3

repair

repair

93