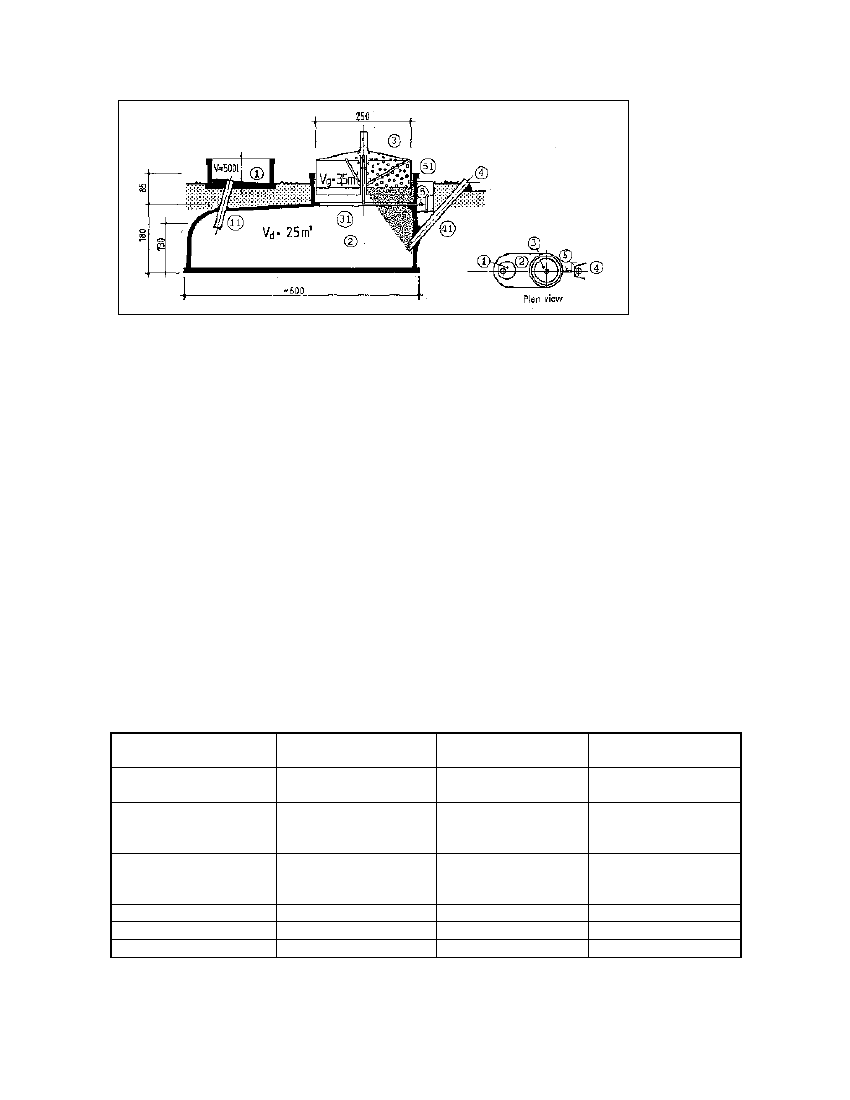

Fig. 5.15: Horizontal biogas plant (KVIC shallow design). 1 Mixing pit, 11 Fill pipe, 2 Digester, 3

Gasholder, 31 Guide frame, 4 Slurry store, 41 Outlet pipe, 5 Gas pipe, 51 Water trap (Source:

OEKOTOP / KVIC 1978)

Horizontal plants (cf. fig. 5.15)

Horizontal biogas plants are usually chosen when shallow installation is called for (groundwater,

rock). They are made of masonry or concrete.

Advantages: Shallow construction despite large slurry space.

Drawbacks: Problems with gas-space leakage, difficult elimination of scum.

Plants with separate gasholders

Masonry dome plants are sometimes equipped with separate gasholders. That approach always

involves substantial extra cost and therefore is rarely recommended. Plants with separate

gasholders are justifiable, when the points of gas consumption are a considerable distance away

from the digester (at least 1 00 m).

Altematively, a separate gasholder could be useful for restoring the utility value of, say, a fixed-

dome plant that has been found to leak at an elevated pressure level.

Table 5.7: Comparison of various plant designs (Source: OEKOTOP)

Design:

Criteria:

Design principle

Main components

digester/gasholder

Preferred substrates

Anticipated useful life

Digester volume (Vd)

Suitability:

Floating-drum

Water-jacket

Fixed dome

continuous-feed, mixed

digester

masonry digester, floating

metal gasholder

animal excrements, with

or without vegetable

waste

8-12 years

6-100 m³

continuous-feed, mixed

digester

masonry digester,

floating metal gasholder

in sep. water jacket

animal excrements with

or without vegetable

waste

10-15 years

6-100 m³

continuous-feed, mixed

digester with slurry store

masonry with

displacement pit

animal excrements plus

vegetable waste

12-20 years

6-20 m³

51