Table 3.10: Effects of digested slurry on crop yields (Source: Chengdu 1980)

Plants tested

Sweet potatoes

Rice

corn (maize)

Cotton

Quantity of digested slurry

(m³ /ha)

17

15

22.5

22.5

Yield

with digested

slurry

(kg/ha)

24000

6500

5000

1300

with liquid

manure

21500

6000

4600

1200

Increase

(kg/ha)

21500

500

400

100

(%)

12

8

9

8

The importance of digested slurry as a fertilizer is underlined by the answers to the following

questions:

- How much chemical fertilizer cap be saved with no drop in yield?

- Which yield levels can be achieved by fertilizing with digested slurry, as compared to the same

amount of undigested material, e.g. stored or fermented liquid manure?

- By how much can yields be increased over those from previously unfertilized soil? Depending

on those answers, a certain monetary value can be attached to digested slurry, whereas the

labor involved in preparing and applying the fertilizer must be given due consideration.

Storing and application of digested slurry

With a view to retaining the fertilizing quality of digested slurry, it should be stored only briefly in

liquid form in a closed pit or tank and then applied to the fields. Liquid storage involves a certain

loss of nitrogen due to the evaporation of ammonia. For that reason, and in order to limit the size of

the required storage vessels (a 30-day supply corresponds to about 50% of the biogas plant

volume), the storage period should be limited to 2-4 weeks. The resultant quasi-continuous mode of

field fertilization (each 2-4 weeks), however, is in opposition to the standing criteria of optimum

application, according to which fertilizer should only be applied 2-4 times per year, and then only

during the plants' growth phase, when they are able to best exploit the additional nutrient supply.

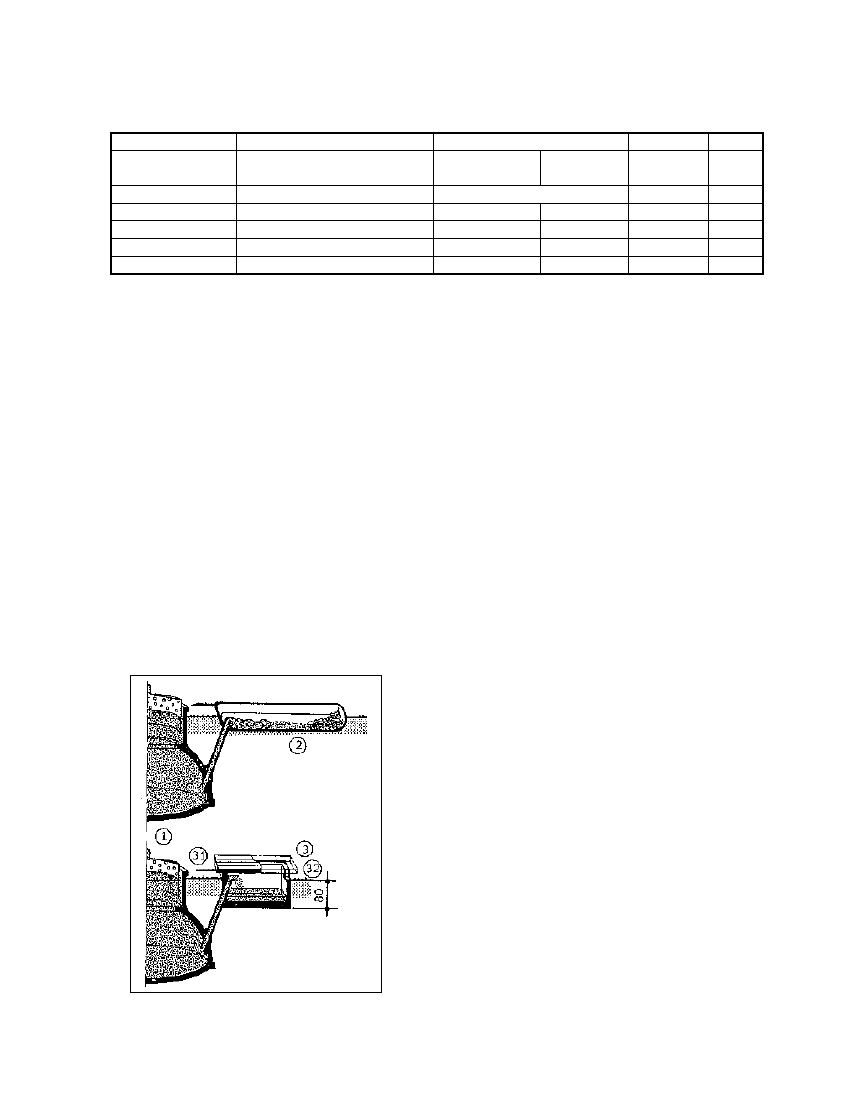

Fig. 3.7: Slurry storage and composting. 1 Biogas

plant, 2 Slurry composting pit with green cover 3

Masonry storage pit (V = 10 Sd), 31 Sturdy wooden

cover, 32 Overflow (Source: OEKOTOP)

27