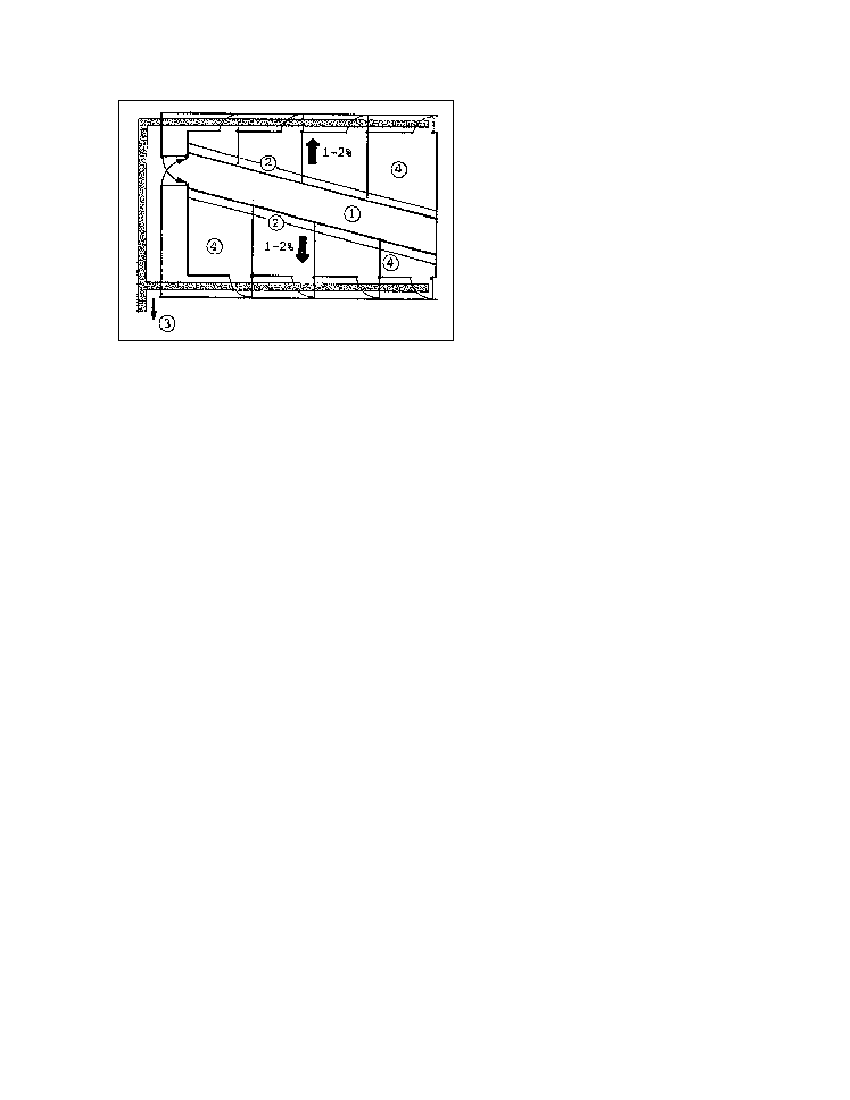

Fig. 3.6: Piggery with group bays (no litter).

1 Feeding aisle, 2 Feeding trough, 3

Floating gutter leading to the biogas plant,

4 Bay (pigpen) (Source: Manuel et Preas

D levage No. 3, 1977)

Liquid manure from swine normally has better flow properties than liquid manure from cattle, the

main reason being that swine eat less fibrous material. Additionally, though, swine drop more urine

than dung.

In tropical countries, few pigsties have fully or partially slotted floors. Most pigs are kept in group

bays. Figure 3.6 shows a schematic representation of a piggery with bays of different size to

accommodate animals of various weight categories. The animals are moved in groups from one bay

to the next as they grow.

Chicken coops

Hens kept in battery-brooding cages never have litter. Despite the name, straw yards can be

managed with or without litter.

In either system, the dry droppings are collected, transferred to the biogas plant and diluted to make

them flowable. Feathers and sand are always problematic, since they successfully resist removal

from the substrate. In many cases, the coop is only cleaned and disinfected once after the entire

population is slaughtered. As a rule such systems are not suitable as a source of substrate for

biogas plants.

3.4 Fertilizing with digested slurry

The practice of regular organic fertilizing is still extensively unknown in most tropical and subtropical

countries. Due, however, to steady intensification of agricultural methods, e.g. abbreviated fallow

intervals, some form of purposeful organic fertilizing, naturally including the use of digested slurry as

fertilizer, would be particularly useful as a means of maintaining tropical soil fertility. Since Third

World farmers have little knowledge of or experience in organic fertilizing methods, particularly with

regard to the use of digested slurry, the scope of the following discussion is limited to the general

plantgrowth efficiency factors of digested slurry.

Fermentation-induced modification of substrate

- Anaerobic digestion draws carbon, hydrogen and oxygen out of the substrate. The essential

plant nutrients (N, P, K) remain, at least in principle, in place. The composition of fertilizing

agents in digested slurry depends on the source material and therefore can be manipulated

within certain limits.

24