5.4.1 Mixing pit

In the mixing pit, the substrate is diluted with water and agitated to yield a homogeneous slurry.

The fibrous material is raked off the surface, and any stones or sand settling to the bottom are

cleaned out after the slurry is admitted to the digester.

The useful volume of the mixing pit should amount to 1.5-2 times the daily input quantity. A rock or

wooden plug can be used to close off the inlet pipe during the mixing process. A sunny location can

help warm the contents before they are fed into the digester in order to preclude thermal shock due

to the cold mixing water. In the case of a biogas plant that is directly connected to animal housing, it

is advisable to install the mixing pit deep enough to allow installation of a floating gutter leading

directly into the pit. Care must also be taken to ensure that the low position of the mixing pit does

not result in premature digestion and resultant slurry formation. For reasons of hygiene, toilets

should have a direct connection to the inlet pipe.

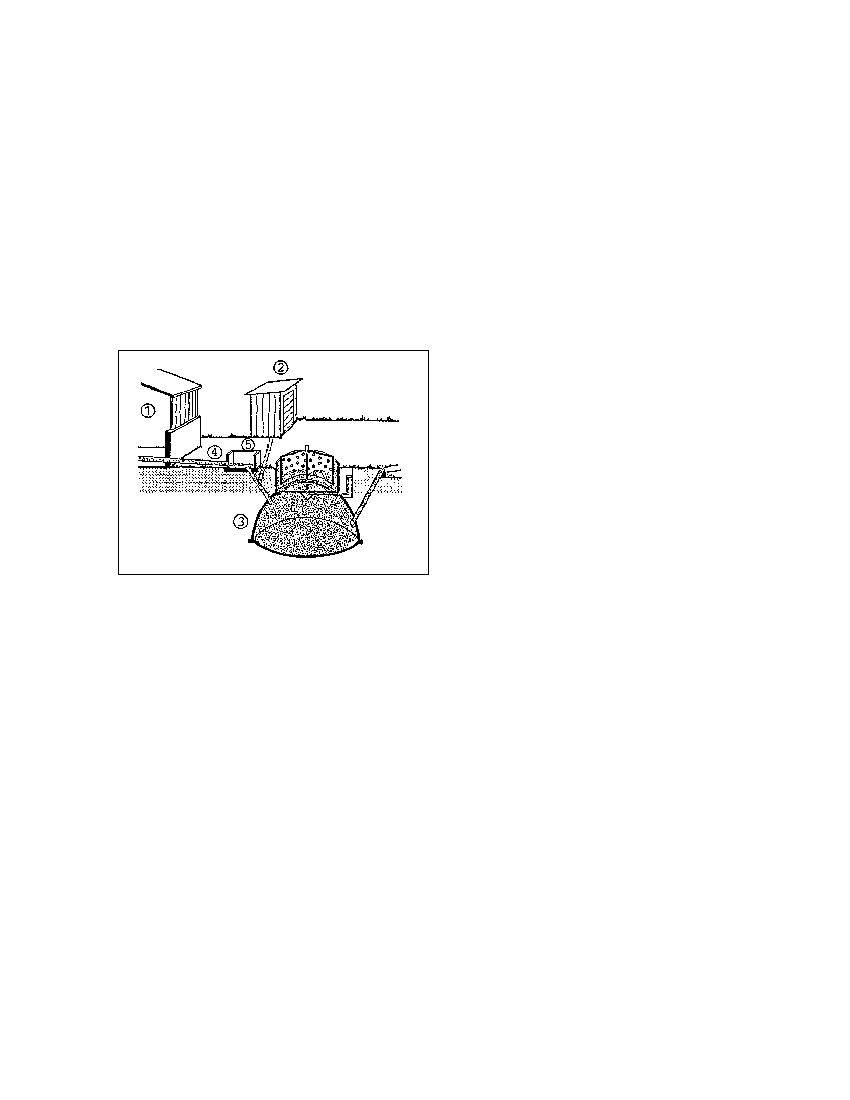

Fig. 5.17: Mixing pit, gutter and toilet drain

pipe. 1 Barn, 2 Toilet, 3 Biogas plant, 4 Feed

gutter 2% gradient), 5 Mixing pit (Source:

OEKOTOP)

5.4.2 Inlet and outlet

The inlet (feed) and outlet (discharge) pipes lead straight into the digester at a steep angle. For

liquid substrate, the pipe diameter should be 10-15 cm, while fibrous substrate requires a diameter

of 20 - 30 cm. Plastic or concrete pipes are preferred.

Note:

- Both the inlet pipe and the outlet pipe must be freely accessible and straight, so that a rod

can be pushed through to eliminate obstructions and agitate the digester contents;

- The pipes should penetrate the digester wall at a point below the slurry level. The points of

penetration should be sealed off and reinforced with mortar.

- The inlet pipe ends higher than the outlet pipe in the digester in order to promote more

uniform throughflow. In a fixed-dome plant, the inlet pipe defines the bottom limit of the

gasholder, thus providing overpressure relief.

- In a floating-drum plant, the end of the outlet pipe determines the digester's slurry level.

54