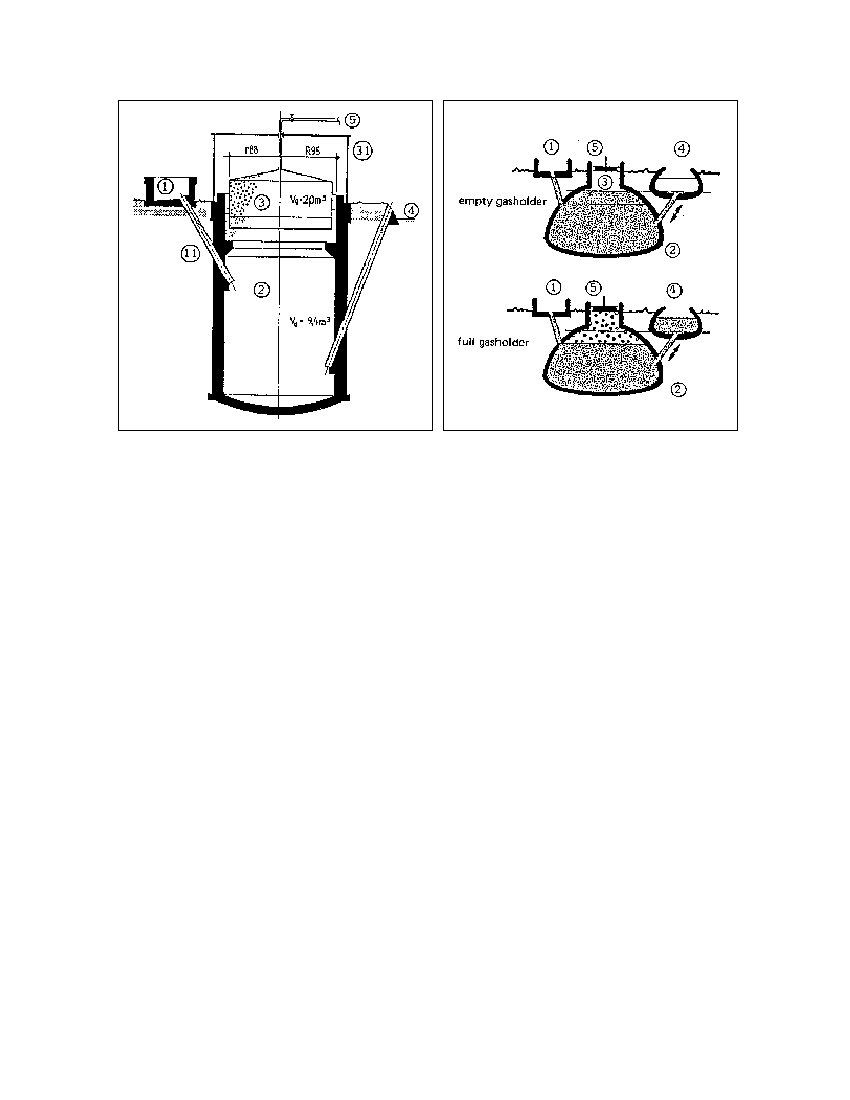

Fig. 5.8: Cylindrical plant design for quarrystone

masonry construction. 1 Mixing pit, 11 Fill pipe,

Digester, 3 Gasholder, 31 Guide frame,

4 Slurry store, 5 Gas pipe (Source: KVIC)

Fig. 5.9: Basic function of a fixed dome

biogas plant. 1 Mixing pit, 2 Digester, 3 2

Gasholder, 4 Displaceinent pit, 5 Gas pipe

(Source: OEKOTOP)

5.3.2 Fixed-dome plants

A fixed-dome plant comprises a closed, dome-shaped digester with an immovable, rigid gasholder

and a displacement pit. The gas collects in the upper part of the digester. Gas production increases

the pressure in the digester and pushes slurry into the displacement pit. When gas is extracted, a

proportional amount of slurry flows back into the digester.

The gas pressure does not remain constant in a fixed-dome plant, but increases with the amount of

stored gas. Consequently, a special-purpose pressure controller or a separate floating gasholder is

needed to achieve a constant supply pressure. The digesters of such plants are usually made of

masonry, with paraffin or bituminous paint applied to the gas-flled area in order to make it gastight.

Fixed-dome plants can handle fibrous substances in combination with animal excrements, since the

motion of the substrate breaks up the scum each day. The plant is a continous-feed type, but can

accept several days' worth of substrate at a time, if the displacement pit is large enough.

Fixed-dome plants must be covered with earth up to the top of the gas-filled space as a

precautionary measure (internal pressure up to 0.1-0.15 bar). As a rule, the size of the digester

does not go beyond 20 m³, corresponding to a gasholder volume of 3-4 m³. The earth cover makes

them suitable for colder climates, and they can be heated as necessary.

Advantages: Fixed-dome plants are characterized by low initial cost and a long useful life, since no

moving or rusting parts are involved. The basic design is compact and well-insulated.

Drawbacks: Masonry is not normally gaslight (porosity and cracks) and therefore requires the use of

special sealants. Cracking often causes irreparable leaks. Fluctuating gas pressure complicates gas

utilization, and plant operation is not readily understandable.

47