The conversion of spark-ignition engines is evaluated as follows:

- Gasoline engines are readily available in the form of vehicle motors, but their useful life

amounts to a mere 3000 - 4000 operating hours.

- The conversion effort essentially consists of adding a (well-tuned) gas mixer.

- Gasoline engines are not as durable as diesel engines.

Engine selection and operation

Speed

Since biogas burns relatively slowly, biogas-fueled engines should be operated at

- 1300-2000 r.p.m. (diesel)

- 1500-3000 r.p.m. (spark-ignition)

The standard speeds for such engines are 1500 and 3000 r.p.m. (50 Hz) or 1800/3600 r.p.m. (60

Hz) because of connecting a generator. For direct-power applications, i.e. a V-belt drive, the

transmission ratio should ensure that the engine operates within its best efficiency range (= lowest

fuel consumption) under normal-power conditions.

(f engine-end pulley speed of machine)/(f machine-end pulley)= (speed of machine)/(speed of

engine)

Consumption

Depending on the gas composition, barometric pressure and type of engine, the specific

consumption will amount to 0.5-0.8 m³/ kWh, i.e. a 10-kW engine will use 5-8 m³ biogas per hour. In

a dual-fuel setup, the biogas consumption rate can be reduced by lowering the biogas fraction.

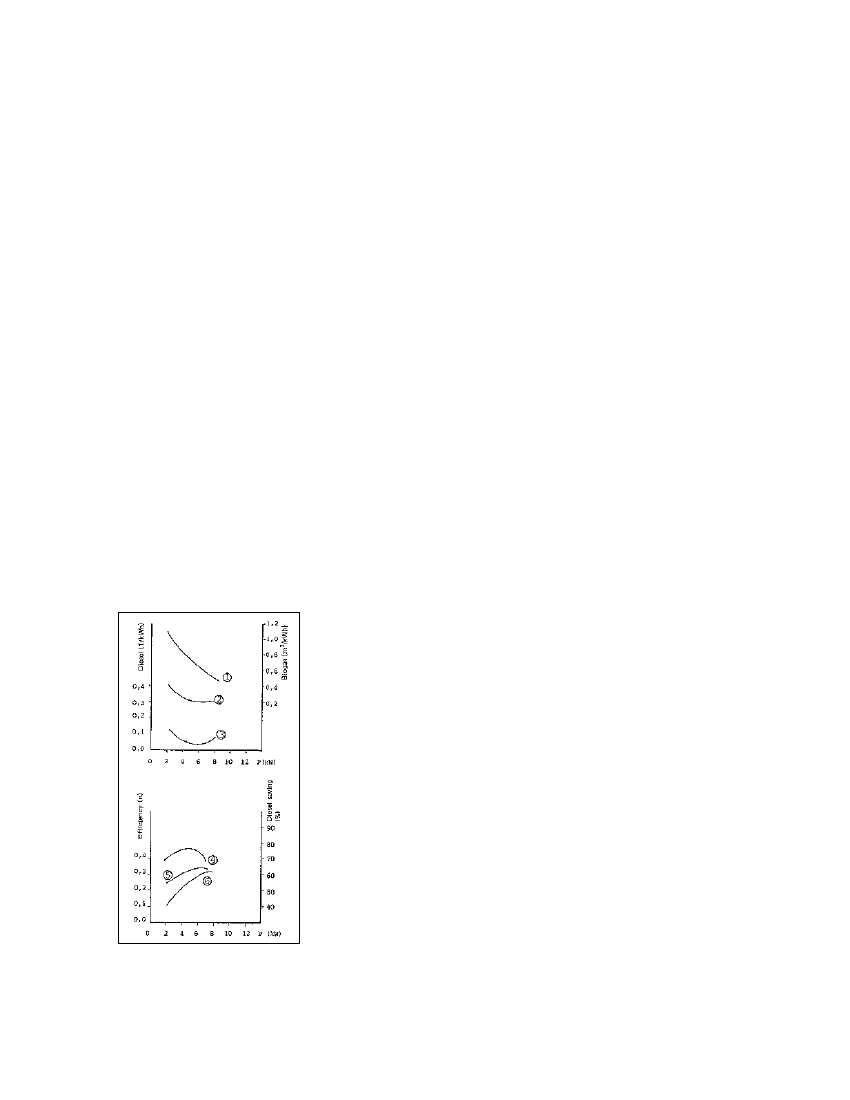

Fig. 5.36: Consumption of diesel and biogas by a 10-kW engine (1

cyl., 1000 ccm), 1300 m above sea level, running at 1500 r.p.m. 1

Biogas consumption in dual-fuel operation, 2 Diesel consumption in

pure diesel operation, 3 Diesel consumption in dual-fuel operation,

4 Diesel saving, 5 Efficiency in diesel operation, 6 Efficiency in dual-

fuel operation (Source: Mitzlaff 1986)

78