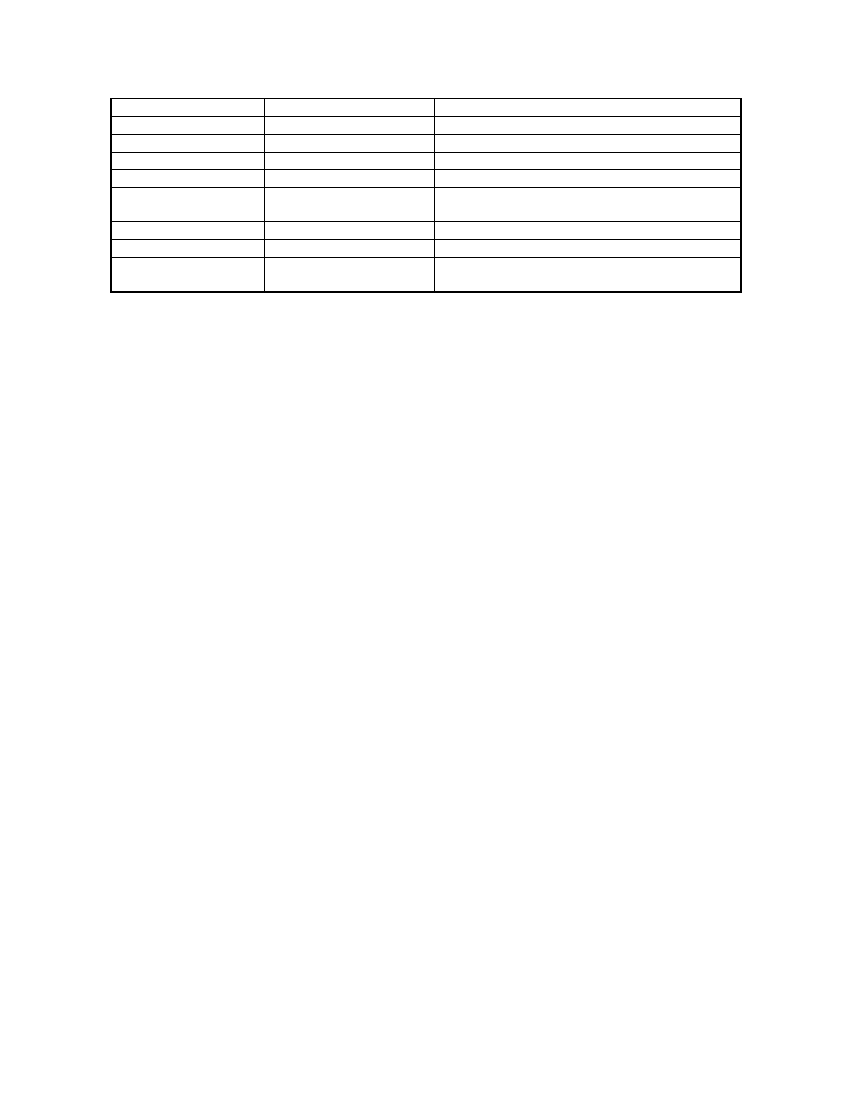

TS-content

Daily gas production

Specific gas production

Gas utilization

250 m³/d

0.6 m³/m³ Vd

MWM gas-powered

motor-generator set

15 kWel

Operating time

Power generation

22 h/d

270 kWh/d

4-8%

450 m³/d

0.55 m³/m³ Vd

Deutz gas-powered

motor generator set

32 kWel, with exhaust heat recovery for heating

water

10 h/d

245 kWh/d

Combination gas-oil burner for steam sterilizer, 130-

355 kW

1Fluctuation due to seasonal factors (rainy/dry season)

Slaughterhouses

The proper disposal of paunch and intestinal contents (fecal matter), dung and urine and, in some

cases, blood and offal is not always ensured in slaughterhouses. Such residues can be put to good

use in a biogas plant, since:

- the energy demand and the substrate incidence are extensively parallel and usually involve

short distances for transportation;

- the biogas technique is more cost-efffcient and yields more energy than aerobic processes, so

that most slaughterhouses could cover their own energy demand with such a plant.

Slaughterhouses in developing countries span a wide size range. Consequently, various techniques

are needed for treating and/or disposing of waste materials and wastewater. While little experience

has been gained to date in connection with the disposal of slaughterhouse wastes via biogas

technology, the following assessment can nonetheless be arrived at:

- Small, village-scale slaughterhouses

in which 50 - 100 animals are slaughtered each week can make use of simple agricultural biogas

plants like those discussed in chapter 5 for disposing of all offal and other residues, and the

digested slurry can be used as agricultural fertilizer.

The main problem in such plants is the formation of a thick layer of scum made up of the contents of

paunches and fecal matter. For that reason, and in order to achieve good hygiene, retention times

of 100 days or more are considered practical.

- Medium-sized slaughterhouses (200-500 slaughterings per week)

Here, too, biogas plants are able to provide complete disposal, although large-scale types like those

used in Ferkessedougou are required. Sometimes, it is a good idea to separate the solid wastes

from the wastewater and possibly compost the solids.

- Large-scale slaughterhouses

Most such slaughterhouses are quite similar to those found in European cities and are usually

located in urban areas. Consequently, proper waste disposal and wastewater purification call for

integrated concepts in line with European standards.

86