Thus, the external pressure applied by the surrounding earth must be greater at all points than the

internal forces (pE > pW). For the procedure on how to estimate earth force and hydrostatic forces,

please refer to chapter 10.1.4.

Round and spherical shapes are able to accept the highest forces—and do it uniformly. Edges and

corners lead to peak stresses and, possibly, to tensile stresses and cracking. Such basic

considerations suggest the use of familiar cylindrical and dome designs allowing:

- inexpensive, material-sparing construction based on modest material thicknesses

- a good volume/surface ratio and

- better (read: safe) stability despite simple construction.

The dome foundation has to contend with the highest loads. Cracks occurring around the

foundation can spread out over the entire dome, but are only considered dangerous in the case of

fixed-dome plants. A rated break ring can be provided to limit cracking.

Groundwork

The first step of building the plant consists of defining the plant level line with a taut string. All

important heights and depths are referred to that line.

Excavation

The pit for the biogas plant is excavated by hand in the shape of a cylindrical shaft. The shaft

diameter should be approx. 2 x 50 cm larger than that of the digester. If the soil is adequately

compact and adhesive, the shaft wall can be vertical. Otherwise it will have to be inclined. The

overburden, if reusable, is stored at the side and used for backfilling and compacting around the

finished plant.

Foundation

The foundation slab must be installed on well-smoothed ground that is stable enough to minimize

settling. Any muddy or loose subsoil (fill) must be removed and replaced by sand or stones. The

bottom must have the shape of a shallow inverted dome to make it more stable and rigid than a flat

slab. Quarrystones, bricks and mortar or concrete can be used as construction materials. Steel

reinforcing rods are only necessary for large plants, and then only in the form of peripheral ties

below the most heavily burdened part, i.e. the dome foundation.

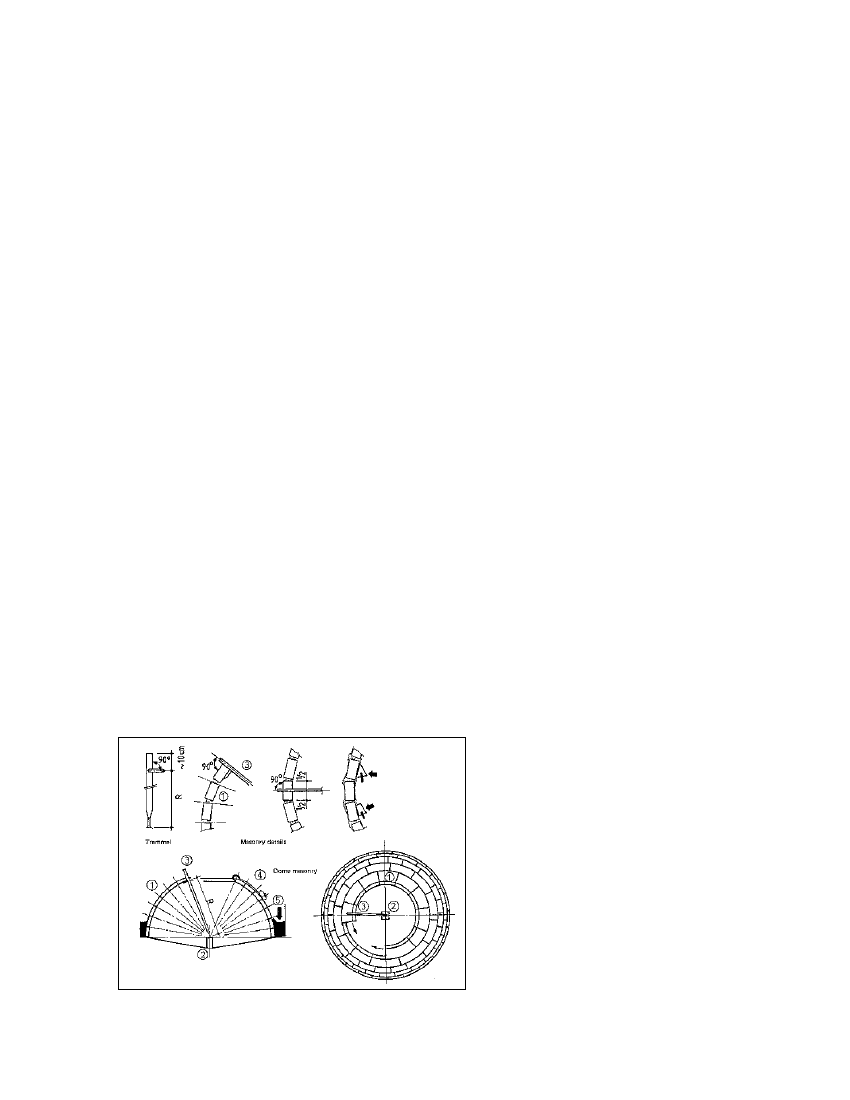

Fig. 5.21: Construction of a spherical

dome from masonry. 1 Dome/masonry, 2

Establishing the centerpoint, 3 Trammel,

4 Brick clamp with counterweights, 5

Backfill (Source: Sasse 1984)

56