User familiarization

The plant owner should be familiarized with the details of plant operation and maintenance at the

time of commissioning. It is important that he be not only familiarized with the theory of function but

given ample opportunity to practice using all parts of the plant. The user-familiarization procedure

should be built up around an operational/maintenance checklist (cf. table 7.2).

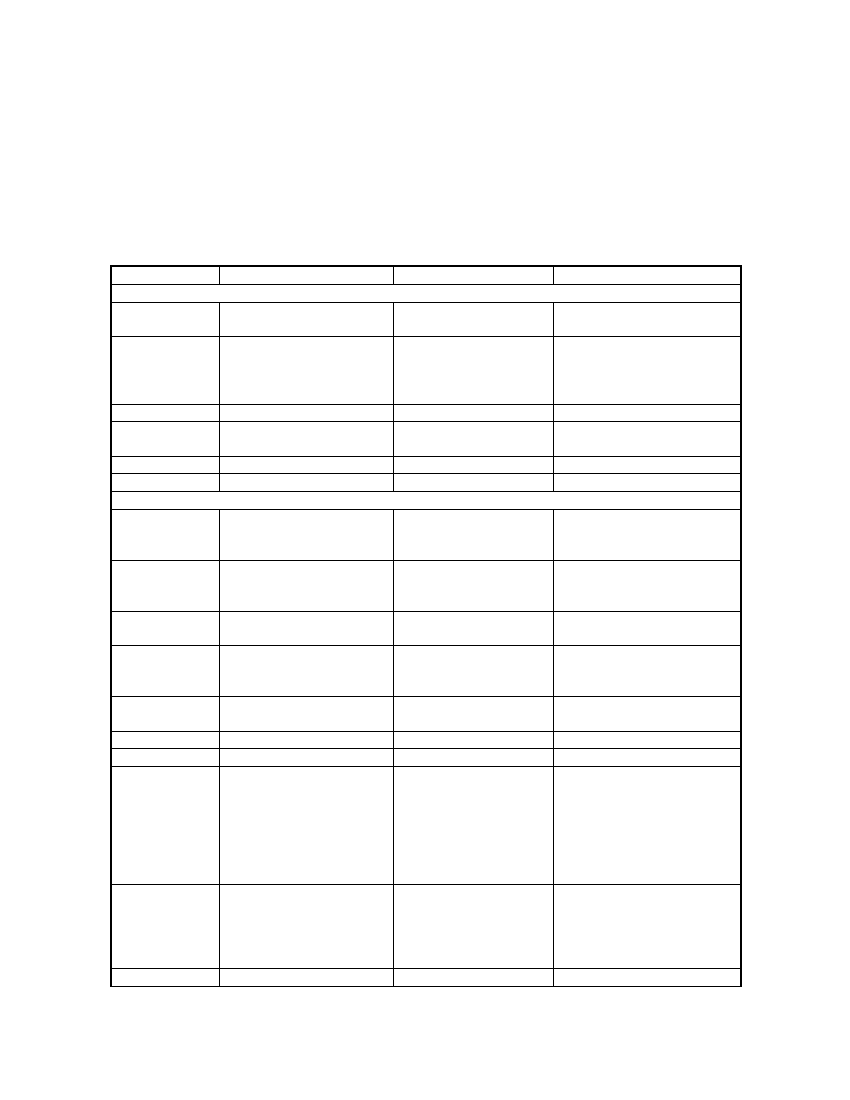

Table 7.1: Checklist for the inspection and acceptance of biogas plants (Source: OEKOTOP)

Check item

Nonconformance

I Interim inspection prior to backfilling

Site • unsuitable

Digester masonry • cracked/broken bricks/ stones

• seriously false dimen- signs

• improperly jointed masonry

inlet/outlet pipes

• false configuration

• poor backfilling

II Final inspection and acceptance

Rendering in

• cracks, sandy rendering, low

digester/

strength, cavities, poorly worked

gasholder

edges and coving

Masonry seal

coats

Mixing pit/slurry

sotre/displacement

pit

Inlet/outlet pipes

Earth fill

Water-fill check of

all component

heights(relative):

inlet, outlet,

digester, gas-

holder cf. chapter

7.1

• cracks, flaws, thin spots, voids

• cracks, poor workman-ship

• plugged, poorly worked

transitions

• insufficient fill height

• poorly compacted earth

for floating-drum plants:

• water in mixing pit, too low;

water spills over the digester,

i.e. digester too low; outlet too

low for fixed dome plants:

• water above gas zero line -

Remedy

• dismantle/demolish the

plant

• demolish the masonry

• fix with mortar, incl.

foundation

• demolish

• refill

a) for the gas space of a

fixed-dome plant: replace

rendering

b) for the slurry space: repair

or add a new layer of

rendering (usually sufficient)

• renew the coating

• demolish or repair

• remove mortar plug, repair

with mortar/ concrete

• recompact, add

• shorten the outlet

• add wall height to digester

Remarks

Fixed-dome plants in particular call

for high-quality work. Tearing

down the plant at this point is often

. the least-painful solution

Ensure high-quality work man-ship

for fixed-dome plants

(applies only to fixed-dome plants)

Differentiation must be made

between nonconfor mances that

impair the plant's function and

nonconformances that merely

prevent optimal utilization

90