There are two central demands to be placed on the stock-farming system in relation to biogas

utilization:

- permanent or part-time stabling or penning and

- proximity of the stables or pens to the place of gas utilization (usually the farmhouse).

If the distance between the stables/pens and the place of gas utilization is considerable, either the

substrate must be hauled to the biogas plant (extra work) or the gas must be transferred to the

place of use (cost of installing a supply pipe). Either of the two would probably doom the biogas

plant to failure. The best set of circumstances is given, when

- the animal excrements can flow directly into the biogas plant by exploiting a natural

gradient,

- the distance of flow is short, and

- the stables have a concrete floor to keep contamination like soil and sand from getting into

the plant while allowing collection of urine.

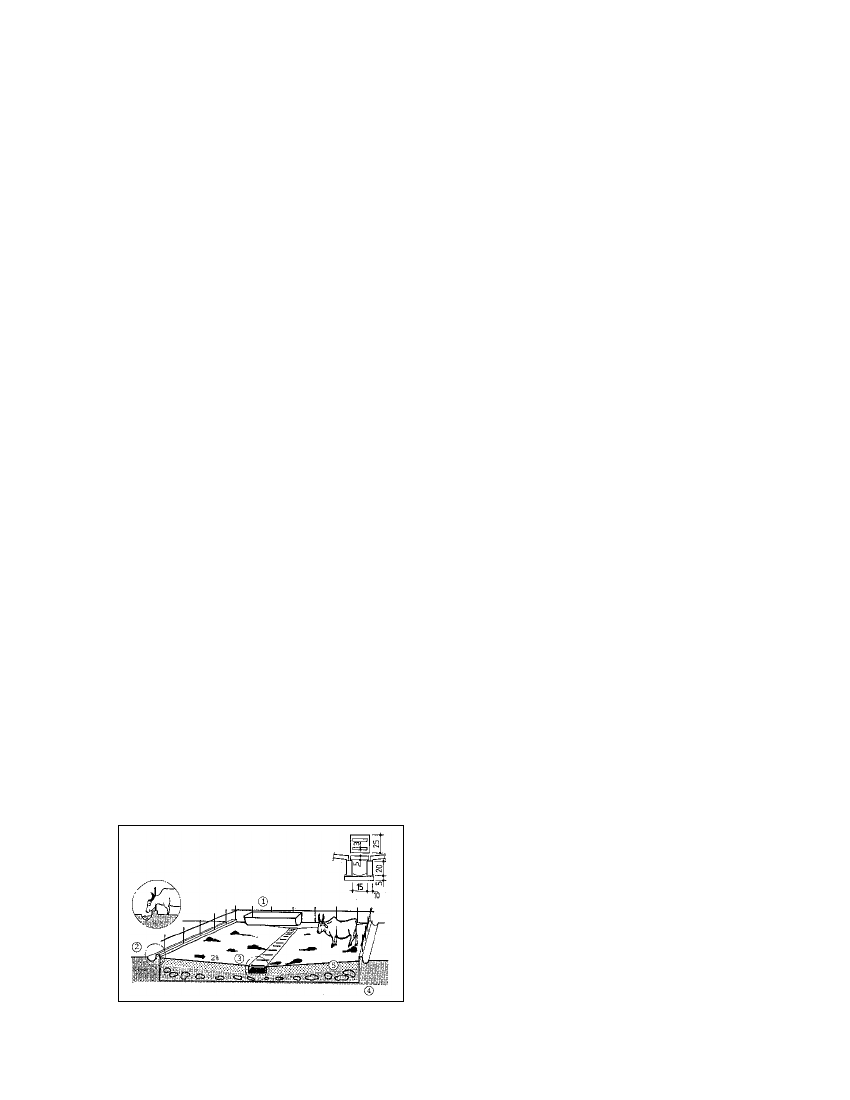

Cattle pens

Dung from earth-floor pens has a very high total-solids content (TS up to 60%), and the urine is lost.

Daily collection is tedious and there is no way to prevent sand from getting into the digester.

Consequently, at the same time a biogas plant is being installed, concrete floors should be installed

in such pens and provided with a collecting channel. This increases the total cost of the biogas

plant, but is usually justified, since it lowers the subsequent work input, helps ensure regular feeding

of the plant, reduces the chance of hoof disease and keeps sand and stones out of the digester.

The overall effect is to enhance acceptance of the biogas plant.

The collecting channels can be designed as open gutters or covered ducts. Concrete split tiles

serve well as construction material for the second (more expensive) version. The slots should be

about 2 - 3 cm wide, i.e. wide enough to let the dung pass through, but not wide enough to cause

injury to the animals.

Cattle dung dries rapidly in a hot climate, particularly if the pen has no roof. The cleaning water also

serves to liquefy the dung and reduce its TS content to 5-10%. for the purposes of fermentation.

The main advantage of this system is that the pens can be cleaned and the biogas plant filled in a

single operation. The collecting channel should be designed to yield a floating-manure system with

gates at the ends, so that a whole day's dung and cleaning water can collect at once. The

advantages:

- easy visual control of the daily substrate input,

- prevention of collecting-channel blockage due to dung sticking to the walls and drying out,

- adding the substrate at the warmest time of day, which can be very important in areas with

low nighttime temperatures.

Fig. 3.3: Pen with concrete floor and collecting

channel for dung and urine.

1. Water through, 2 Feeding through, 3 Collecting

channel, 4 Sand and rocks, 5 Concrete (Source:

OEKOTOP)

22