Zirconium

Did you know...

SOS believes education gives a better chance in life to children in the developing world too. SOS Children works in 45 African countries; can you help a child in Africa?

| Zirconium | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

|

40Zr

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Appearance | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

silvery white |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| General properties | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Name, symbol, number | zirconium, Zr, 40 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Pronunciation | / z ər ˈ k oʊ n i ə m / zər-KOH-ni-əm | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Metallic category | transition metal | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Group, period, block | 4, 5, d | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Standard atomic weight | 91.224 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Electron configuration | [Kr] 5s2 4d2 2, 8, 18, 10, 2 |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| History | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Discovery | Martin Heinrich Klaproth (1789) | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| First isolation | Jöns Jakob Berzelius (1824) | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Physical properties | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Phase | solid | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Density (near r.t.) | 6.52 g·cm−3 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Liquid density at m.p. | 5.8 g·cm−3 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Melting point | 2128 K, 1855 °C, 3371 °F | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Boiling point | 4682 K, 4409 °C, 7968 °F | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Heat of fusion | 14 kJ·mol−1 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Heat of vaporization | 573 kJ·mol−1 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Molar heat capacity | 25.36 J·mol−1·K−1 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Vapor pressure | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Atomic properties | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Oxidation states | 4, 3, 2, 1 ( amphoteric oxide) |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Electronegativity | 1.33 (Pauling scale) | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Ionization energies | 1st: 640.1 kJ·mol−1 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2nd: 1270 kJ·mol−1 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3rd: 2218 kJ·mol−1 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Atomic radius | 160 pm | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Covalent radius | 175±7 pm | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Miscellanea | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Crystal structure | hexagonal close-packed | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Magnetic ordering | paramagnetic | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Electrical resistivity | (20 °C) 421 nΩ·m | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Thermal conductivity | 22.6 W·m−1·K−1 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Thermal expansion | (25 °C) 5.7 µm·m−1·K−1 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Speed of sound (thin rod) | (20 °C) 3800 m·s−1 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Young's modulus | 88 GPa | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Shear modulus | 33 GPa | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Bulk modulus | 91.1 GPa | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Poisson ratio | 0.34 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Mohs hardness | 5.0 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Vickers hardness | 903 MPa | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Brinell hardness | 650 MPa | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| CAS registry number | 7440-67-7 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Most stable isotopes | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Main article: Isotopes of zirconium | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

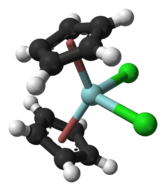

Zirconium is a chemical element with the symbol Zr, atomic number 40 and atomic mass of 91.224. The name of zirconium is taken from the mineral zircon, the most important source of zirconium. It is a lustrous, grey-white, strong transition metal that resembles titanium. Zirconium is mainly used as a refractory and opacifier, although it is used in small amounts as an alloying agent for its strong resistance to corrosion. Zirconium forms a variety of inorganic and organometallic compounds such as zirconium dioxide and zirconocene dichloride, respectively. Five isotopes occur naturally, three of which are stable. Zirconium compounds have no known biological role.

Characteristics

Zirconium is a lustrous, greyish-white, soft, ductile and malleable metal which is solid at room temperature, though it becomes hard and brittle at lower purities. In powder form, zirconium is highly flammable, but the solid form is far less prone to ignition. Zirconium is highly resistant to corrosion by alkalis, acids, salt water and other agents. However, it will dissolve in hydrochloric and sulfuric acid, especially when fluorine is present. Alloys with zinc become magnetic below 35 K.

Zirconium's melting point is 1855 °C (3371 °F), and its boiling point is 4371 °C (7900 °F). Zirconium has an electronegativity of 1.33 on the Pauling scale. Of the elements within d-block, zirconium has the fourth lowest electronegativity after yttrium, lutetium and hafnium.

At room temperature zirconium exhibits a hexagonally close packed crystal structure, α-Zr, which changes to β-Zr a body-centered cubic crystal structure at 863 °C. Zirconium exists in the β-phase until the melting point.

ZrZn2 is one of only two substances to exhibit superconductivity and ferromagnetism simultaneously, with the other being UGe2.

Isotopes

Naturally occurring zirconium is composed of five isotopes. 90Zr, 91Zr, 92Zr and 94Zr are stable. 94Zr can undergo double beta decay (not observed experimentally) with a half-life of more than 1.10×1017 years. 96Zr has a half-life of 2.4×1019 years, making it the longest-lived radioisotope of zirconium. Of these natural isotopes, 90Zr is the most common, making up 51.45% of all zirconium. 96Zr is the least common, comprising only 2.80% of zirconium.

Twenty-eight artificial isotopes of zirconium have been synthesized, ranging in atomic mass from 78 to 110. 93Zr is the longest-lived artificial isotope, with a half-life of 1.53×106 years. 110Zr, the heaviest isotope of zirconium, is also the shortest-lived, with an estimated half-life of only 30 milliseconds. Radioactive isotopes at or above mass number 93 decay by β−, whereas those at or below 89 decay by β+. The only exception is 88Zr, which decays by ε.

Five isotopes of zirconium also exist as metastable isomers: 83mZr, 85mZr, 89mZr, 90m1Zr, 90m2Zr and 91mZr. Of these, 90m2Zr has the shortest half-life at 131 nanoseconds. 89mZr is the longest lived with a half-life of 4.161 minutes.

Occurrence

Zirconium has a concentration of about 130 mg/kg within the Earth's crust and about 0.026 μg/L in sea water. It is not found in nature as a native metal, reflecting its intrinsic instability with respect to water. The principal commercial source of zirconium is the silicate mineral, zircon (ZrSiO4), which is found primarily in Australia, Brazil, India, Russia, South Africa and the United States, as well as in smaller deposits around the world. 80% of zircon mining occurs in Australia and South Africa. Zircon resources exceed 60 million metric tons worldwide and annual worldwide zirconium production is approximately 900,000 metric tons. Zirconium also occurs in more than 140 other minerals, including the commercially useful ores baddeleyite and kosnarite.

Zr is relatively abundant in S-type stars, and it has been detected in the sun and in meteorites. Lunar rock samples brought back from several Apollo program missions to the moon have a quite high zirconium oxide content relative to terrestrial rocks.

Production

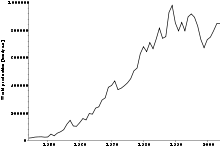

Zirconium is a by-product of the mining and processing of the titanium minerals ilmenite and rutile, as well as tin mining. From 2003 to 2007, zircon prices have steadily increased from $360 to $840 per metric ton.

Upon being collected from coastal waters, zircon-containing sand is purified by spiral concentrators to remove lighter materials, which are then placed back into the water safely, as they are all natural components of beach sand. Using magnetic separation, the titanium ores ilmenite and rutile are removed.

Most zircon is used directly in commercial applications, but a few percent is converted to the metal. Most Zr metal is produced by the reduction of the zirconium(IV) chloride with magnesium metal in the Kroll process. Commercial-quality zirconium for most uses still has a content of 1% to 3% hafnium. This contaminant is unimportant except in nuclear applications. The resulting metal is sintered until sufficiently ductile for metalworking.

Separation of zirconium and hafnium

Commercial zirconium metal typically contains 1–2.5% of hafnium, which is not problematic because the chemical properties of hafnium and zirconium are rather similar. Their neutron-absorbing properties differ strongly, however, necessitating the separation of hafnium from zirconium for applications involving nuclear reactors. Several separation schemes are in use. The liquid-liquid extraction of the thiocyanate-oxide derivatives, exploits the slightly greater solubility of the hafnium derivative in methyl isobutyl ketone vs water. This method is used mainly in United States. Zr and Hf can also be separated by fractional crystallization of potassium hexafluorozirconate (K2ZrF6), which is less soluble in water than the analogous hafnium derivative. Fractional distillation of the tetrachlorides, also called extractive distillation, is used primarily in Europe. A quadruple VAM (vacuum arc melting) process, combined with hot extruding and different rolling applications is cured using high-pressure high-temperature gas autoclaving, resulting in reactor-grade zirconium that is about 10 times more expensive than the hafnium-contaminated commercial grade. The separated hafnium can be used for control rods of the reactor. The separation of hafnium is especially important for nuclear applications since Hf has very high neutron absorption cross-section, 600 times higher than zirconium, and therefore has to be removed for reactor applications.

Compounds

Like other transition metals, zirconium forms a wide range of inorganic compounds and coordination complexes. In general, these compounds are colourless diamagnetic solids wherein Zr has the oxidation state IV+. Far fewer Zr(III) compounds are known, and Zr(II) is very rare.

Oxides, nitrides and carbides

The most common oxide is zirconium dioxide, ZrO2, also referred to as zirconia. This colourless solid has exceptional fracture toughness and chemical resistance, especially in its cubic form. These properties make zirconia useful as a thermal barrier coating, although it is also a common diamond substitute. Zirconium tungstate is an unusual substance in that it shrinks in all directions when heated, whereas most other substances expand when heated. Zirconyl chloride is a rare water-soluble zirconium complex, it has the relatively complicated formula [Zr4(OH)12(H2O)16]Cl8.

Zirconium carbide and zirconium nitride are refractory solids. The carbide is used to make drilling tools and cutting edges. Zirconium(II) hydride is also known.

Halides and pseudohalides

All four common halides are known, ZrF4, ZrCl4, ZrBr4 and ZrI4. All have polymeric structures and are far less volatile than the corresponding monomeric titanium tetrahalides. All tend to hydrolyse to give the so-called oxyhalides and dioxides. The corresponding tetra alkoxides are also known. Unlike the halides, the alkoxides dissolve in nonpolar solvents.

Organic derivatives

Organozirconium chemistry is the study of compounds containing a carbon-zirconium bond. The first such compound was zirconocene dibromide ((C5H5)2ZrBr2), reported in 1952 by Birmingham and Wilkinson. Schwartz's reagent, prepared in 1970 by P. C. Wailes and H. Weigold, is a metallocene used in organic synthesis for transformations of alkenes and alkynes. Zirconium is also a component of some Ziegler-Natta catalysts, used to produce polypropylene. This application exploits the ability of zirconium to reversibly form bonds to carbon. Most complexes of Zr(II) are derivatives of zirconacene, one example being (C5Me5)2Zr(CO)2.

History

The zirconium-containing mineral zircon and related minerals ( jargoon, hyacinth, jacinth, ligure) were mentioned in biblical writings. The mineral was not known to contain a new element until 1789, when Klaproth analyzed a jargoon from the island of Ceylon (now Sri Lanka). He named the new element Zirkonerde (zirconia). Humphry Davy attempted to isolate this new element in 1808 through electrolysis, but failed. Zirconium metal was first obtained in an impure form in 1824 by Berzelius by heating a mixture of potassium and potassium zirconium fluoride in an iron tube.

The crystal bar process (also known as the Iodide Process), discovered by Anton Eduard van Arkel and Jan Hendrik de Boer in 1925, was the first industrial process for the commercial production of metallic zirconium. The process involves the formation and subsequent thermal decomposition of zirconium tetraiodide. This method was superseded in 1945 by the much cheaper Kroll process developed by William Justin Kroll, in which zirconium tetrachloride is reduced by magnesium:

- ZrCl4 + 2 Mg → Zr + 2 MgCl2

Applications

Approximately 900,000 tonnes of Zr ores were produced commercially in 1995, mostly as zircon.

Compounds

The great majority of zircon is used directly in a variety of high temperature applications. This material is refractory and hard, as well as resistant to chemical attack. Because of these properties, zircon finds many applications, few of which are highly publicized. Its main use is as an opacifier, conferring a white, opaque appearance to ceramic materials. Because of its chemical resistance, zircon is also used in aggressive environments, such as moulds for molten metals. Zirconium dioxide (ZrO2) is used in laboratory crucibles, metallurgical furnaces, as a refractory material, and it can be sintered into a ceramic knife. Zircon (ZrSiO4) is cut into gemstones for use in jewellery.

Metal

A small fraction of the zircon is converted to the metal, which finds various niche applications. Because of zirconium's excellent resistance to corrosion, it is often used as an alloying agent in materials that are exposed to aggressive environments, such as surgical appliances, light filaments and watch cases. The high reactivity of zirconium toward oxygen, apparent only at high temperatures, is the basis of some specialised applications as explosive primers and as getters in vacuum tubes. The same behaviour is probably the basis of the use of Zr nano-particles as pyrophoric material in explosive weapons such as the BLU-97/B Combined Effects Bomb for incendiary effect.

Nuclear applications

Cladding for nuclear reactor fuels consumes about 1% of the zirconium supply. For this purpose, it is mainly used in the form of zircaloys. The benefits of Zr alloys is their low neutron-capture cross-section and good resistance to corrosion under normal service conditions. The development of efficient methods for the separation of zirconium from hafnium was required for this application.

One disadvantage of zirconium alloys is their reactivity toward water at high temperatures leading to the formation of hydrogen gas and to the accelerated degradation of the fuel rod cladding:

- Zr + 2 H2O → ZrO2 + 2 H2

This exothermic reaction is very slow below 100 °C, but at temperature above 900 °C the reaction is rapid. Most metals undergo similar reactions. The redox reaction is relevant to the instability of fuel assemblies at high temperatures. This reaction was responsible for a small hydrogen explosion first observed inside the reactor building of Three Mile Island nuclear power plant in 1979, but then, the containment building was not damaged. The same reaction occurred in the reactors 1, 2 and 3 of the Fukushima I Nuclear Power Plant (Japan) after the reactors cooling was interrupted by the earthquake and tsunami disaster of March 11, 2011 leading to the Fukushima I nuclear accidents. After venting of hydrogen in the maintenance hall of these three reactors, the explosive mixture of hydrogen with air oxygen detonated, severely damaging the installations and at least one of the containment buildings. To avoid explosion, the direct venting of hydrogen to the open atmosphere would have been a preferred design option. Now, to prevent the risk of explosion in many pressurized water reactor (PWR) containment buildings, a catalyst-based recombinator is installed to rapidly convert hydrogen and oxygen into water at room temperature before the explosivity limit is reached.

Space and aeronautic industries

Materials fabricated from zirconium metal and its oxide (ZrO2) are used in space vehicle parts for their resistance to heat. Zirconia is also a component in some abrasives, such as grinding wheels and sandpaper.

High temperature parts such as combustors, blades and vanes in jet engines and stationary gas turbines are to an increasing extent being protected by thin ceramic layers. These ceramic layers are usually composed by a mixture of zirconia and yttria.

Positron emission tomography cameras

The isotope 89Zr has been recently applied to the tracking and quantification of molecular antibodies with positron emission tomography (PET) cameras (a method called "immuno-PET"). Immuno-PET has reached maturity in terms of technical development and is now entering the phase of wide-scale clinical applications. Until recently, radiolabeling with 89Zr was a complicated procedure requiring multiple steps. In 2001–2003 an improved multistep procedure was developed using a succinylated derivative of desferrioxamine B (N-sucDf) as a bifunctional chelate, and a better way of binding 89Zr to mAbs was reported in 2009. The new method is fast, consists of only two steps, and uses two widely available ingredients: 89Zr and the appropriate chelate.

Defunct applications

Zirconium carbonate (3ZrO2·CO2·H2O) was used in lotions to treat poison ivy but was discontinued because it occasionally caused skin reactions.

Safety

Zirconium has no known biological role, and zirconium compounds are of low toxicity. The human body contains, on average, only 1 milligram of zirconium, and daily intake is approximately 50 μg per day. Zirconium content in human blood is as low as 10 parts per billion. Aquatic plants readily take up soluble zirconium, but it is rare in land plants. Seventy percent of plants have no detectable zirconium content, and those that do have as little as 5 parts per billion.

Short-term exposure to zirconium powder can cause irritation, but only contact with the eyes requires medical attention. Inhalation of zirconium compounds can cause skin and lung granulomas. Zirconium aerosols can cause pulmonary granulomas. Persistent exposure to zirconium tetrachloride resulted in increased mortality in rats and guinea pigs and a decrease of blood hemoglobin and red blood cell in dogs. The U.S. Occupational Safety and Health Administration recommends a 5 mg/m3 time weighted average limit and a 10 mg/m3 short-term exposure limit for air dust.