Propeller (marine)

About this schools Wikipedia selection

This wikipedia selection has been chosen by volunteers helping SOS Children from Wikipedia for this Wikipedia Selection for schools. Child sponsorship helps children one by one http://www.sponsor-a-child.org.uk/.

A propeller is essentially a type of fan which transmits power by converting rotational motion into thrust for propulsion of a vehicle such as an aircraft, ship, or submarine through a mass such as water or air, by rotating two or more twisted blades about a central shaft, in a manner analogous to rotating a screw through a solid. The blades of a propeller act as rotating wings (the blades of a propeller are in fact wings or airfoils), and produce force through application of both Bernoulli's principle and Newton's third law, generating a difference in pressure between the forward and rear surfaces of the airfoil-shaped blades and by accelerating a mass of air rearward.

History

The principle employed in using a screw propeller is used in sculling. It is part of the skill of propelling a Venetian gondola but was used in a less refined way in other parts of Europe and probably elsewhere. For example, propelling a canoe with a single paddle using a "j-stroke" involves a related but not identical technique. In China, sculling, called "lu", was also used by the 3rd century AD .

In sculling, a single blade is moved through an arc, from side to side taking care to keep presenting the blade to the water at the effective angle. The innovation introduced with the screw propeller was the extension of that arc through more than 360° by attaching the blade to a rotating shaft. In practice, there is nearly always more than one blade so as to balance the forces involved. The exception is a single-blade propeller system.

The origin of the actual screw propeller starts with Archimedes, who used a screw to lift water for irrigation and bailing boats, so famously that it became known as the Archimedes screw. It was probably an application of spiral movement in space (spirals were a special study of Archimedes) to a hollow segmented water-wheel used for irrigation by Egyptians for centuries. Leonardo da Vinci adopted the principle to drive his theoretical helicopter, sketches of which involved a large canvas screw overhead.

In 1784, J. P. Paucton proposed a gyrocopter-like aircraft using similar screws for both lift and propulsion. At about the same time, James Watt proposed using screws to propel boats, although he did not use them for his steam engines. This was not his own invention, though; Toogood and Hays had patented it a century earlier, and it had become an uncommon use as a means of propelling boats since that time.

By 1827 Josef Ressel had invented a screw propeller which had multiple blades fastened around a conical base; this new method of propulsion allowed steam ships to travel at much greater speeds without using sails thereby making ocean travel faster. Propellers remained extremely inefficient and little-utilized until 1835, when Francis Pettit Smith discovered a new way of building propellers. Up to that time, propellers were literally screws, of considerable length. But during the testing of a boat propelled by one, the screw snapped off, leaving a fragment shaped much like a modern boat propeller. The boat moved faster with the broken propeller.

At about the same time, Frédéric Sauvage and John Ericsson applied for patents on vaguely similar, although less efficient shortened screw propellers, leading to an apparently-permanent controversy as to who is the official inventor among those three men. Ericsson became widely famous when he built the “Monitor” an armoured battleship that in 1862 triumphedover the Confederate States’ Merrimac in an American Civil War sea battle.

The first screw propeller to be powered by a gasoline engine, fitted to a small boat (now known as a powerboat) was installed by Frederick Lanchester, also from Birmingham. This was tested in Oxford. The first 'real-world' use of a propeller was by David Bushnell, who used hand-powered screw propellers to motivate his submarine "Turtle" in 1776.

The twisted airfoil (aerofoil) shape of modern aircraft propellers was pioneered by the Wright brothers when they found that all existing knowledge on propellers (mostly naval) was determined by trial and error and that no one knew exactly how they worked. They found that a propeller is essentially the same as a wing and so were able to use data collated from their earlier wind tunnel experiments on wings. They also found that the relative angle of attack from the forward movement of the aircraft was different for all points along the length of the blade, thus it was necessary to introduce a twist along its length. Their original propeller blades are only about 5% less efficient than the modern equivalent, some 100 years later.

Alberto Santos Dumont was another early pioneer, having designed propellers before the Wright Brothers (albeit not as efficient) for his airships. He applied the knowledge he gained from experiences with airships to make a propeller with a steel shaft and aluminium blades for his 14 bis biplane. Some of his designs used a bent aluminium sheet for blades, thus creating an airfoil shape. These are heavily undercambered because of this and combined with the lack of a lengthwise twist made them less efficient than the Wright propellers. Even so, this was perhaps the first use of aluminium in the construction of an airscrew.

Aviation

Aircraft propellers (airscrews)

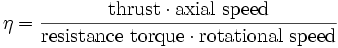

A propeller's efficiency is determined by

.

.

A well-designed propeller typically has an efficiency of around 80% when operating in the best regime. Changes to a propeller's efficiency are produced by a number of factors, notably adjustments to the helix angle(θ), the angle between the resultant relative velocity and the blade rotation direction, and to blade pitch (where θ = Φ + α) . Very small pitch and helix angles give a good performance against resistance but provide little thrust, while larger angles have the opposite effect. The best helix angle is when the blade is acting as a wing producing much more lift than drag.

Propellers are similar in aerofoil section to a low drag wing and as such are poor in operation when at other than their optimum angle of attack. Control systems are required to counter the need for accurate matching of pitch to flight speed and engine speed.

The purpose of varying pitch angle with a variable pitch propeller is to maintain an optimal angle of attack (maximum lift to drag ratio) on the propeller blades as aircraft speed varies. Early pitch control settings were pilot operated, either two-position or manually variable. Later, automatic propellers were developed to maintain an optimum angle of attack. They did this by balancing the centripetal twisting moment on the blades and a set of counterweights against a spring and the aerodynamic forces on the blade. Automatic props had the advantage of being simple and requiring no external control, but a particular propeller's performance was difficult to match with that of the aircraft's powerplant. An improvement on the automatic type was the constant-speed propeller. Constant speed propellers allow the pilot to select a rotational speed for maximum engine power or maximum efficiency, and a propeller governor acts as a closed-loop controller to vary propeller pitch angle as required to maintain the RPM commanded by the pilot. In most aircraft this system is hydraulic, with engine oil serving as the hydraulic fluid. However, electrically controlled propellers were developed during World War II and saw extensive use on military aircraft.

On some variable-pitch propellers, the blades can be rotated parallel to the airflow to reduce drag and increase gliding distance in case of an engine failure. This is called feathering. Feathering propellers were developed for military fighter aircraft prior to World War II, as a fighter is more likely to experience an engine failure due to the inherent danger of combat. Feathering propellers are used on multi-engine aircraft and are meant to reduce drag on a failed engine. When used on powered gliders and single-engine turbine powered aircraft they increase the gliding distance. Most feathering systems for reciprocating engines sense a drop in oil pressure and move the blades toward the feather position, and require the pilot to pull the prop control back to disengage the high-pitch stop pins before the engine reaches idle RPM. Turbopropeller control systems usually utilize a negative torque sensor in the reduction gearbox which moves the blades toward feather when the engine is no longer providing power to the propeller. Depending on design, the pilot may have to push a button to override the high-pitch stops and complete the feathering process, or the feathering process may be totally automatic.

In some aircraft (e.g., the C-130 Hercules), the pilot can manually override the constant speed mechanism to reverse the blade pitch angle, and thus the thrust of the engine. This is used to help slow the plane down after landing in order to save wear on the brakes and tires, but in some cases also allows the aircraft to back up on its own.

A further consideration is the number and the shape of the blades used. Increasing the aspect ratio of the blades reduces drag but the amount of thrust produced depends on blade area, so using high aspect blades can lead to the need for a propeller diameter which is unusable. A further balance is that using a smaller number of blades reduces interference effects between the blades, but to have sufficient blade area to transmit the available power within a set diameter means a compromise is needed. Increasing the number of blades also decreases the amount of work each blade is required to perform, limiting the local Mach number - a significant performance limit on propellers.

Contra-rotating propellers use a second propeller rotating in the opposite direction immediately 'downstream' of the main propeller so as to recover energy lost in the swirling motion of the air in the propeller slipstream. Contra-rotation also increases power without increasing propeller diameter and provides a counter to the torque effect of high-power piston engine as well as the gyroscopic precession effects, and of the slipstream swirl. However on small aircraft the added cost, complexity, weight and noise of the system rarely make it worthwhile.

The propeller is usually attached to the crankshaft of the engine, either directly or through a gearbox. Light aircraft sometimes forego the weight, complexity and cost of gearing but on some larger aircraft and some turboprop aircraft it is essential.

A propeller's performance suffers as the blade speed exceeds the speed of sound. As the relative air speed at the blade is rotation speed plus axial speed, a propeller blade tip will reach sonic speed sometime before the rest of the aircraft (with a theoretical blade the maximum aircraft speed is about 845 km/h (Mach 0.7) at sea-level, in reality it is rather lower). When a blade tip becomes supersonic, drag and torque resistance increase suddenly and shock waves form creating a sharp increase in noise. Aircraft with conventional propellers, therefore, do not usually fly faster than Mach 0.6. There are certain propeller-driven aircraft, usually military, which do operate at Mach 0.8 or higher, although there is considerable fall off in efficiency.

There have been efforts to develop propellers for aircraft at high subsonic speeds. The 'fix' is similar to that of transonic wing design. The maximum relative velocity is kept as low as possible by careful control of pitch to allow the blades to have large helix angles; thin blade sections are used and the blades are swept back in a scimitar shape ( Scimitar propeller); a large number of blades are used to reduce work per blade and so circulation strength; contra-rotation is used. The propellers designed are more efficient than turbo-fans and their cruising speed (Mach 0.7–0.85) is suitable for airliners, but the noise generated is tremendous (see the Antonov An-70 and Tupolev Tu-95 for examples of such a design).

Aircraft fans

A fan is a propeller with a large number of blades. A fan therefore produces a lot of thrust for a given diameter but the closeness of the blades means that each strongly affects the flow around the others. If the flow is supersonic, this interference can be beneficial if the flow can be compressed through a series of shock waves rather than one. By placing the fan within a shaped duct – a ducted fan – specific flow patterns can be created depending on flight speed and engine performance. As air enters the duct, its speed is reduced and pressure and temperature increase. If the aircraft is at a high subsonic speed this creates two advantages – the air enters the fan at a lower Mach speed and the higher temperature increases the local speed of sound. While there is a loss in efficiency as the fan is drawing on a smaller area of the free stream and so using less air, this is balanced by the ducted fan retaining efficiency at higher speeds where conventional propeller efficiency would be poor. A ducted fan or propeller also has certain benefits at lower speeds but the duct needs to be shaped in a different manner to one for higher speed flight. More air is taken in and the fan therefore operates at an efficiency equivalent to a larger un-ducted propeller. Noise is also reduced by the ducting and should a blade become detached the duct would contain the damage. However the duct adds weight, cost, complexity and (to a certain degree) drag.

See also Airscrew wind generator.

Transverse axis propellers

Most propellers have their axis of rotation parallel to the fluid flow. There have however been some attempts to power vehicles with the same principles behind vertical axis wind turbines, where the rotation is perpendicular to fluid flow. Most attempts have been unsuccessful. Blades that can vary their angle of attack during rotation have aerodynamics similar to flapping flight. Flapping flight is still poorly understood and almost never seriously used in engineering because of the strong coupling of lift, thrust and control forces.

The fanwing is one of the few types that has actually flown. It takes advantage of the trailing edge of an airfoil to help encourage the circulation necessary for lift.

The Voith-Schneider propeller pictured below is another successful example, operating in water.

Marine

A propeller is the most common propulsor on ships, imparting momentum to a fluid which causes a force to act on the ship.

The ideal efficiency of any size propeller is that of an actuator disc in an ideal fluid. An actual marine propeller is made up of sections of helicoidal surfaces which act together 'screwing' through the water (hence the common reference to marine propellers as "screws"). Three, four, or five blades are most common in marine propellers, although designs which are intended to operate at reduced noise will have more blades. The blades are attached to a boss (hub), which should be as small as the needs of strength allow - with fixed pitch propellers the blades and boss are usually a single casting.

An alternative design is the controllable pitch propeller (CPP), where the blades are rotated normal to the drive shaft by additional machinery - usually hydraulics - at the hub and control linkages running down the shaft. This allows the drive machinery to operate at a constant speed while the propeller loading is changed to match operating conditions. It also eliminates the need for a reversing gear and allows for more rapid change to thrust, as the revolutions are constant. This type of propeller is most common on ships such as tugs where there can be enormous differences in propeller loading when towing compared to running free, a change which could cause conventional propellers to lock up as insufficient torque is generated. The downside of a CPP is the large hub which increases the chance of cavitation and the mechanical complexity which limits transmission power.

For smaller motors there are self-pitching propellers. The blades freely move through an entire circle on an axis at right angles to the shaft. This allows hydrodynamic and centrifugal forces to 'set' the angle the blades reach and so the pitch of the propeller.

A propeller that turns clockwise to produce forward thrust, when viewed from aft, is called right-handed. One that turns anticlockwise is said to be left-handed. Larger vessels often have twin screws to reduce heeling torque, counter-rotating propellers, the starboard screw is usually right-handed and the port left-handed, this is called outward turning. The opposite case is called inward turning. Another possibility is contra-rotating propellers, where two propellers rotate in opposing directions on a single shaft.

Additional designs

An Azimuthing propeller is a vertical axis propeller.

The blade outline is defined either by a projection on a plane normal to the propeller shaft (projected outline) or by setting the circumferential chord across the blade at a given radius against radius (developed outline). The outline is usually symmetrical about a given radial line termed the median. If the median is curved back relative to the direction of rotation the propeller is said to have skew back. The skew is expressed in terms of circumferential displacement at the blade tips. If the blade face in profile is not normal to the axis it is termed raked, expressed as a percentage of total diameter.

Each blade's pitch and thickness varies with radius, early blades had a flat face and an arced back (sometimes called a circular back as the arc was part of a circle), modern propeller blades have aerofoil sections. The camber line is the line through the mid-thickness of a single blade. The camber is the maximum difference between the camber line and the chord joining the trailing and leading edges. The camber is expressed as a percentage of the chord.

The radius of maximum thickness is usually forward of the mid-chord point with the blades thinning to a minimum at the tips. The thickness is set by the demands of strength and the ratio of thickness to total diameter is called blade thickness fraction.

The ratio of pitch to diameter is called pitch ratio. Due to the complexities of modern propellers a nominal pitch is given, usually a radius of 70% of the total is used.

Blade area is given as a ratio of the total area of the propeller disc, either as developed blade area ratio or projected blade area ratio.

History of ship and submarine screw propellers

James Watt of Scotland is generally credited with applying the first screw propeller to an engine, an early steam engine, beginning the use of an hydrodynamic screw for propulsion.

Mechanical ship propulsion began with the steam ship. The first successful ship of this type is a matter of debate; candidate inventors of the 18th century include William Symington, the Marquis de Jouffroy, John Fitch and Robert Fulton, however William Symington's ship the Charlotte Dundas is regarded as the world's "first practical steamboat". Paddlewheels as the main motive source became standard on these early vessels (see Paddle steamer). Robert Fulton had tested, and rejected, the screw propeller.

The screw (as opposed to paddlewheels) was introduced in the latter half of the 18th century. David Bushnell's invention of the submarine ( Turtle) in 1775 used hand-powered screws for vertical and horizontal propulsion. The Bohemian engineer Josef Ressel designed and patented the first practicable screw propeller in 1827. Francis Pettit Smith tested a similar one in 1836. In 1839, John Ericsson introduced the screw propeller design onto a ship which then sailed over the Atlantic Ocean in 40 days. Mixed paddle and propeller designs were still being used at this time (vide the 1858 SS Great Eastern).

In 1848 the British Admiralty held a tug of war contest between a propeller driven ship, Rattler, and a paddle wheel ship, Alecto. Rattler won, towing Alecto astern at 2.8 knots (5 km/h), but it was not until the early 20th century paddle propelled vessels were entirely superseded. The screw propeller replaced the paddles owing to its greater efficiency, compactness, less complex power transmission system, and reduced susceptibility to damage (especially in battle)

Initial designs owed much to the ordinary screw from which their name derived - early propellers consisted of only two blades and matched in profile the length of a single screw rotation. This design was common, but inventors endlessly experimented with different profiles and greater numbers of blades. The propeller screw design stabilized by the 1880s.

In the early days of steam power for ships, when both paddle wheels and screws were in use, ships were often characterized by their type of propellers, leading to terms like screw steamer or screw sloop.

Propellers are referred to as "lift" devices, while paddles are "drag" devices.

Cavitation can occur if an attempt is made to transmit too much power through the screw. At high rotating speeds or under heavy load (high blade lift coefficient), the pressure on the inlet side of the blade can drop below the vapour pressure of the water, resulting in the formation of a pocket of vapour, which can no longer effectively transfer force to the water (stretching the analogy to a screw, you might say the water thread 'strips'). This effect wastes energy, makes the propeller "noisy" as the vapour bubbles collapse, and most seriously, erodes the screw's surface due to localized shock waves against the blade surface. Cavitation can, however, be used as an advantage in design of very high performance propellers, in form of the supercavitating propeller. (See also fluid dynamics). A similar, but quite separate issue, is ventilation, which occurs when a propeller operating near the surface draws air into the blades, causing a similar loss of power and shaft vibration, but without the related potential blade surface damage caused by cavitation. Both effects can be mitigated by increasing the submerged depth of the propeller: cavitation is reduced because the hydrostatic pressure increases the margin to the vapor pressure, and ventilation because it is further from surface waves and other air pockets that might be drawn into the slipstream.

Forces acting on an aerofoil

The force (F) experienced by an aerofoil blade is determined by its area (A), chord (c), velocity (V) and the angle of the aerofoil to the flow, called either angle of incidence or angle of attack ( ), where:

), where:

The force has two parts - that normal to the direction of flow is lift (L) and that in the direction of flow is drag (D). Both are expressed non-dimensionally as:

and

and

Each coefficient is a function of the angle of attack and Reynolds' number. As the angle of attack increases lift rises rapidly from the no lift angle before slowing its increase and then decreasing, with a sharp drop as the stall angle is reached and flow is disrupted. Drag rises slowly at first and as the rate of increase in lift falls and the angle of attack increases drag increases more sharply.

For a given strength of circulation ( ),

),  . The effect of the flow over and the circulation around the aerofoil is to reduce the velocity over the face and increase it over the back of the blade. If the reduction in pressure is too much in relation to the ambient pressure of the fluid, cavitation occurs, bubbles form in the low pressure area and are moved towards the blade's trailing edge where they collapse as the pressure increases, this reduces propeller efficiency and increases noise. The forces generated by the bubble collapse can cause permanent damage to the surfaces of the blade.

. The effect of the flow over and the circulation around the aerofoil is to reduce the velocity over the face and increase it over the back of the blade. If the reduction in pressure is too much in relation to the ambient pressure of the fluid, cavitation occurs, bubbles form in the low pressure area and are moved towards the blade's trailing edge where they collapse as the pressure increases, this reduces propeller efficiency and increases noise. The forces generated by the bubble collapse can cause permanent damage to the surfaces of the blade.

Propeller thrust

Single blade

Taking an arbitrary radial section of a blade at r, if revolutions are N then the rotational velocity is  . If the blade was a complete screw it would advance through a solid at the rate of NP, where P is the pitch of the blade. In water the advance speed is rather lower,

. If the blade was a complete screw it would advance through a solid at the rate of NP, where P is the pitch of the blade. In water the advance speed is rather lower,  , the difference, or slip ratio, is:

, the difference, or slip ratio, is:

where J is the advance coefficient ( ) and p is the pitch ratio (P/D).

) and p is the pitch ratio (P/D).

The forces of lift and drag on the blade, dA, where force normal to the surface is dL:

![\mbox{d}L = \frac {1}{2}\rho V_1^2 C_L dA = \frac {1}{2}\rho C_L[V_a^2(1+a)^2+4\pi^2r^2(1-a')^2]b\mbox{d}r](../../images/639/63928.png)

where:

![\mbox{d}D = \frac {1}{2}\rho V_1^2C_D\mbox{d}A = \frac {1}{2}\rho C_D[V_a^2(1+a)^2+4\pi^2r^2(1-a')^2]b\mbox{d}r](../../images/639/63930.png)

These forces contribute to thrust, T, on the blade:

where

As  ,

,

From this total thrust can be obtained by integrating this expression along the blade. The transverse force is found in a similar manner:

Substituting for  and multiplying by r, gives torque as:

and multiplying by r, gives torque as:

which can be integrated as before.

The total thrust power of the propeller is proportional to  and the shaft power to

and the shaft power to  . So efficiency is

. So efficiency is  . The blade efficiency is in the ratio between thrust and torque:

. The blade efficiency is in the ratio between thrust and torque:

showing that the blade efficiency is determined by its momentum and its qualities in the form of angles  , where

, where  is the ratio of the drag and lift coefficients.

is the ratio of the drag and lift coefficients.

This analysis is simplified and ignores a number of significant factors including interference between the blades and the influence of tip vortices.

Thrust and torque

The thrust, T, and torque, Q, depend on the propeller's diameter, D, revolutions, N, and rate of advance,  , together with the character of the fluid in which the propeller is operating and gravity. These factors create the following non-dimensional relationship:

, together with the character of the fluid in which the propeller is operating and gravity. These factors create the following non-dimensional relationship:

![T = \rho V^2 D^2 [ f_1(\frac {ND}{V_a}), f_2(\frac {v}{V_a D}), f_3(\frac {gD}{V_a^2}) ]](../../images/639/63945.png)

where  is a function of the advance coefficient,

is a function of the advance coefficient,  is a function of the Reynolds' number, and

is a function of the Reynolds' number, and  is a function of the Froude number. Both

is a function of the Froude number. Both  and

and  are likely to be small in comparison to

are likely to be small in comparison to  under normal operating conditions, so the expression can be reduced to:

under normal operating conditions, so the expression can be reduced to:

For two identical propellers the expression for both will be the same. So with the propellers  , and using the same subscripts to indicate each propeller:

, and using the same subscripts to indicate each propeller:

For both Froude number and advance coefficient:

where  is the ratio of the linear dimensions.

is the ratio of the linear dimensions.

Thrust and velocity, at the same Froude number, give thrust power:

For torque:

Actual performance

When a propeller is added to a ship its performance is altered; there is the mechanical losses in the transmission of power; a general increase in total resistance; and the hull also impedes and renders non-uniform the flow through the propeller. The ratio between a propeller's efficiency attached to a ship ( ) and in open water (

) and in open water ( ) is termed relative rotative efficiency.

) is termed relative rotative efficiency.

The overall propulsive efficiency (an extension of effective power ( )) is developed from the propulsive coefficient (PC), which is derived from the installed shaft power (

)) is developed from the propulsive coefficient (PC), which is derived from the installed shaft power ( ) modified by the effective power for the hull with appendages (

) modified by the effective power for the hull with appendages ( ), the propeller's thrust power (

), the propeller's thrust power ( ), and the relative rotative efficiency.

), and the relative rotative efficiency.

/

/ = hull efficiency =

= hull efficiency =

/

/ = propeller efficiency =

= propeller efficiency =

/

/ = relative rotative efficiency =

= relative rotative efficiency =

/

/ = shaft transmission efficiency

= shaft transmission efficiency

Producing the following:

The terms contained within the brackets are commonly grouped as the quasi-propulsive coefficient (QPC,  ). The QPC is produced from small-scale experiments and is modified with a load factor for full size ships.

). The QPC is produced from small-scale experiments and is modified with a load factor for full size ships.

Wake is the interaction between the ship and the water with its own velocity relative to the ship. The wake has three parts - the velocity of the water around the hull; the boundary layer between the water dragged by the hull and the surrounding flow; and the waves created by the movement of the ship. the first two parts will reduce the velocity of water into the propeller, the third will either increase or decrease the velocity depending on whether the waves create a creast or trough at the propeller.

Types of marine propellers

At present, several types of marine propellers have been built for a wide variety of marine vehicles.

Controllable pitch propeller

At present, one of the newest and best type of propeller is the controllable pitch propeller. This propeller has several advantages with ships. These advantages include: the least drag depending on the speed used, the ability to move the seavessel backwards, and the ability to use the "vane"-stance, which gives the least waterresistance when not using the propeller (eg when the sails are used instead).

Skewback propeller

An advanced type of propeller used on German Type 212 submarines is called a skewback propeller. As in the scimitar blades used on some aircraft, the blade tips of a skewback propeller are swept back against the direction of rotation. In addition, the blades are tilted rearward along the longitudinal axis, giving the propeller an overall cup-shaped appearance. This design preserves thrust efficiency while reducing cavitation, and thus makes for a quiet, stealthy design.

See Also: Astern propulsion.