Saturn V

Background to the schools Wikipedia

SOS believes education gives a better chance in life to children in the developing world too. A good way to help other children is by sponsoring a child

The first Saturn V, AS-501, before the launch of Apollo 4 |

|

| Function | Manned LEO and Lunar launch vehicle |

|---|---|

| Manufacturer | Boeing ( S-IC) North American ( S-II) Douglas ( S-IVB) |

| Country of origin | United States |

| Size | |

| Height | 110.6 m (363 ft) |

| Diameter | 10.1 m (33 ft) |

| Mass | 3,038,500 kg (6,699,000 lb) |

| Stages | 3 |

| Capacity | |

| Payload to LEO | 118,000 kg (260,000 lb) |

| Payload to Lunar orbit |

47,000 kg (100,000 lb) |

| Associated rockets | |

| Family | Saturn |

| Derivatives | Saturn INT-21 |

| Comparable | N1 rocket |

| Launch history | |

| Status | Retired |

| Launch sites | LC-39, Kennedy Space Centre |

| Total launches | 13 (including INT-21) |

| Successes | 13 (see note) |

| Failures | 0 |

| Partial failures | 2 (see Apollo 6 and Apollo 13) |

| First flight | November 9, 1967 ( SA-501) |

| Last flight | December 6, 1972 ( May 14, 1973 - INT-21) |

| First Stage - S-IC | |

| Engines | 5 Rocketdyne F-1 |

| Thrust | 34.02 MN (7,648,000 lbf) |

| Burn time | 150 seconds |

| Fuel | RP-1/ LOX |

| Second Stage - S-II | |

| Engines | 5 Rocketdyne J-2 |

| Thrust | 5 MN (1,000,000 lbf) |

| Burn time | 360 seconds |

| Fuel | LH2/ LOX |

| Third Stage - S-IVB | |

| Engines | 1 Rocketdyne J-2 |

| Thrust | 1 MN (225,000 lbf) |

| Burn time | 165 + 335 seconds (2 burns) |

| Fuel | LH2/ LOX |

The Saturn V (pronounced 'Saturn Five', popularly known as the Moon Rocket) was a multistage liquid-fuel expendable rocket used by NASA's Apollo and Skylab programs from 1967 until 1973. In total NASA launched thirteen Saturn V rockets with no loss of payload. It remains the most powerful launch vehicle ever brought to operational status, from a height, weight and payload standpoint. The Russian Energia, which flew only two test missions in the late 1980s, had slightly more takeoff thrust.

The largest production model of the Saturn family of rockets, the Saturn V was designed under the direction of Wernher von Braun at the Marshall Space Flight Centre in Huntsville, Alabama, with Boeing, North American Aviation, Douglas Aircraft Company, and IBM as the lead contractors. The three stages of the Saturn V were developed by various NASA contractors, but following a sequence of mergers and takeovers all of them are now owned by Boeing.

Background

In 1957 the Soviet Union launched Sputnik 1, the first artificial satellite. Lyndon B. Johnson—at the time Senate Majority Leader and later President—recalled feeling "the profound shock of realizing that it might be possible for another nation to achieve technological superiority over this great country of ours." The resulting Sputnik crisis continued, and by 1961, when Soviet cosmonaut Yuri Gagarin orbited the Earth aboard Vostok 1 during the first human spaceflight, many people in the United States felt the Soviets had developed a considerable lead in the Space Race.

On May 25, 1961, President Kennedy announced that America would attempt to land a man on the Moon by the end of the decade. At that time, the only experience the United States had with human spaceflight was the 15-minute suborbital flight of Alan Shepard aboard Freedom 7. No rocket then available was capable of propelling a manned spacecraft to the Moon in one piece. The Saturn I was in development, but would not fly for six months. Although larger than other contemporary rockets, it would require several launches to place all the components of a lunar spacecraft in orbit. The much larger Saturn V had not been designed, although its powerful F-1 engine had already been developed and test fired.

Mission configuration

Early in the planning process, NASA considered three leading ideas for the moon mission: Earth Orbit Rendezvous, Direct Ascent, and Lunar Orbit Rendezvous (LOR). A direct ascent configuration would launch a larger rocket which would land directly on the lunar surface, while an Earth orbit rendezvous would launch two smaller spacecraft which would combine in Earth orbit. A LOR mission would involve a single rocket launching a single spacecraft, but only a small part of that spacecraft would land on the moon. That smaller landing module would then rendezvous with the main spacecraft, and the crew would return home.

NASA at first dismissed LOR as a riskier option, given that an orbital rendezvous had yet to be performed in Earth orbit, much less in lunar orbit. Several NASA officials, including Langley Research Centre engineer John Houbolt and NASA Administrator George Low, argued that a Lunar Orbit Rendezvous provided the simplest landing on the moon, the most cost–efficient launch vehicle and, perhaps most importantly, the best chance to accomplish a lunar landing within the decade. Other NASA officials were convinced, and LOR was officially selected as the mission configuration for the Apollo program on 7 November, 1962.

Development

C-1 to C-4

Between 1960 and 1962, the Marshall Space Flight Centre (MSFC) designed rockets that could be used for various missions.

The C-1 was developed into the Saturn I, and the C-2 rocket was dropped early in the design process in favour of the C-3, which was intended to use two F-1 engines on its first stage, four J-2 engines for its second stage, and an S-IV stage, using six RL-10 engines.

NASA planned to use the C-3 as part of the Earth Orbit Rendezvous concept, with at least four or five launches needed for a single mission, but MSFC was already planning an even bigger rocket, the C-4, which would use four F-1 engines on its first stage, an enlarged C-3 second stage, and the S-IVB, a stage with a single J-2 engine, as its third stage. The C-4 would need only two launches to carry out an Earth Orbit Rendezvous mission.

C-5

On January 10, 1962, NASA announced plans to build the C-5. The three-stage rocket would consist of five F-1 engines for the first stage, five J-2 engines for the second stage, and a single, additional J-2 engine for the third stage. The C-5 was designed for the higher payload capacity necessary for a lunar mission, and could carry up to 41,000 kg into lunar orbit.

The C-5 would undergo component testing even before the first model was constructed. The rocket's third stage would be utilized as the second stage for the C-IB, which would serve both to demonstrate proof of concept and feasibility for the C-5, but would also provide flight data critical to the continued development of the C-5. Rather than undergoing testing for each major component, the C-5 would be tested in an "all-up" fashion, meaning that the first test flight of the rocket would include complete versions of all three stages. By testing all components at once, far fewer test flights would be required before a manned launch.

The C-5 was confirmed as NASA's choice for the Apollo Program in early 1963, and was given a new name—the Saturn V.

Technology

The Saturn V's huge size and payload capacity dwarfed all other previous rockets which had successfully flown at that time. Over 363 feet (110.6 m) high and 33 feet (10 m) (without fins) in diameter, with a total mass of over three thousand short tons and a payload capacity of 260,000 pounds (118,000 kg) to LEO, Comparatively, at 364 feet, the Saturn V is just one foot shorter than St Paul's Cathedral in London, and only cleared the doors of the VAB by 6 ft (1.82 m) when rolled out. In contrast, the Redstone used on Freedom 7, the first manned American spaceflight, was just under 11 feet longer than the S-IVB stage, and less powerful than the Launch Escape System rockets mounted on the Apollo command module.

Saturn V was principally designed by the Marshall Space Flight Centre in Huntsville, Alabama, although numerous major systems, including propulsion, were designed by subcontractors. It used the powerful new F-1 and J-2 rocket engines for propulsion. When tested, these engines shattered the windows of nearby houses. Designers decided early on to attempt to use as much technology from the Saturn I program as possible. As such, the S-IVB third stage of the Saturn V was based on the S-IV second stage of the Saturn I. The instrument unit that controlled the Saturn V shared characteristics with that carried by the Saturn I.

Stages

The Saturn V consisted of three stages — the S-IC first stage, S-II second stage and the S-IVB third stage — and the instrument unit. All three stages used liquid oxygen (LOX) as an oxidizer. The first stage used RP-1 for fuel, while the second and third stages used liquid hydrogen (LH2). The upper stages also used small solid-fuelled ullage motors that helped to separate the stages during the launch, and to ensure that the liquid propellants were in a proper position to be drawn into the pumps.

S-IC first stage

The S-IC was built by The Boeing Company at the Michoud Assembly Facility, New Orleans, where the Space Shuttle External Tanks are now constructed. Most of its mass of over two thousand metric tonnes at launch was propellant, in this case RP-1 rocket fuel and liquid oxygen oxidizer. It was 138 feet (42 m) tall and 33 feet (10 m) in diameter, and provided over 34 MN (7.64 million pounds force) of thrust to get the rocket through the first 61 kilometers of ascent. The five F-1 engines were arranged in a cross pattern. The centre engine was fixed, while the four outer engines could be hydraulically turned ("gimballed") to control the rocket. In flight, the centre engine was turned off earlier to limit acceleration.

S-II second stage

The S-II was built by North American Aviation at Seal Beach, California. Using liquid hydrogen and liquid oxygen, it had five J-2 engines in a similar arrangement to the S-IC, also using the outer engines for control. The S-II was 81 feet and 7 inches (24.9 m) tall with a diameter of 33 feet (10 m), identical to the S-IC, and thus is the largest cryogenic stage ever built. The second stage accelerated the Saturn V through the upper atmosphere with 5.1 MN of thrust (in vacuum). When loaded, significantly more than 90 percent of the mass of the stage was propellant, however, the ultra-lightweight design had led to two failures in structural testing. Instead of having an intertank structure to separate the two fuel tanks as was done in the S-IC, the S-II used a common bulkhead that was constructed from both the top of the LOX tank and bottom of the LH2 tank. It consisted of two aluminium sheets separated by a honeycomb structure made of phenolic resin. This had to insulate against the 70 °C (125 °F) temperature difference between the two tanks. The use of a common bulkhead saved 3.6 metric tons in weight. Like the S-IC, the S-II was transported by sea.

S-IVB third stage

The S-IVB was built by the Douglas Aircraft Company at Huntington Beach, California. It had one J-2 engine and used the same fuel as the S-II. The S-IVB used a common bulkhead to insulate the two tanks. It was 58 feet and 7 inches (17.85 m) tall with a diameter of 21 feet and 8 inches (6.60 m) and was also designed with high mass efficiency, though not quite as aggressively as the S-II. This stage was used twice during the mission: first in a 2.5 min burn for the orbit insertion after second stage cutoff, and later for the trans lunar injection (TLI) burn, lasting about 6 mins. Two liquid-fueled auxiliary propulsion system units mounted at the aft end of the stage were used for attitude control during the parking orbit and the trans-lunar phases of the mission. The two APSs were also used as ullage engines to help settle the fuel prior to the translunar injection burn.

The S-IVB was the only rocket stage of the Saturn V small enough to be transported by plane, in this case the Guppy. Apart from the interstage adapter, this stage is nearly identical to the second stage of the Saturn IB rocket.

Instrument unit

The Instrument Unit was built by IBM and rode atop the third stage. It was constructed at the Space Systems Centre in Huntsville. This computer controlled the operations of the rocket from just before liftoff until the S-IVB was discarded. It included guidance and telemetry systems for the rocket. By measuring the acceleration and vehicle attitude, it could calculate the position and velocity of the rocket and correct for any deviations.

Range safety

In the event of an abort requiring the destruction of the rocket, the range safety officer would remotely shut down the engines and after several seconds send another command for the shaped explosive charges attached to the outer surfaces of the rocket to detonate. These would make cuts in fuel and oxidizer tanks to disperse the fuel quickly and to minimize mixing. The pause between these actions would give time for the crew to escape using the Launch Escape Tower or (in the later stages of the flight) the propulsion system of the Service module. A third command, "safe", was used after the S-IVB stage achieved the orbit to irreversibly deactivate the self-destruct system. The system was also inactive as long as the rocket was still on the launch pad.

Comparisons

The Soviet counterpart of the Saturn V was the N-1 rocket. The Saturn V was taller, heavier, had more liftoff thrust, and greater payload, but the N-1's first stage diameter was larger. The N1 had four test launches before the program was canceled, each resulting in the vehicle catastrophically failing early in the flight. The first stage of Saturn V used five powerful engines rather than the 30 smaller engines of the N-1, necessary as the Soviets had not developed similarly powerful engines at that time. During two launches, Apollo 6 and Apollo 13, the Saturn V was able to recover from engine loss incidents. The N-1 likewise was designed to compensate for engine failures, but the system never successfully saved a launch from failure. Overall, the main reason for the N-1's failures seems to be traceable to lack of all-up testing of the first stage, in turn due to insufficient funding.

The three-stage Saturn V had a peak thrust of at least 34.02 MN (SA-510 and subsequent) and a lift capacity of 118,000 kg to LEO. The SA-510 mission (Apollo 15) had a liftoff thrust of 7.823 million pounds (34.8 MN). The SA-513 mission (Skylab) had slightly greater liftoff thrust of 7.891 million pounds (35.1 MN). No other operational launch vehicle has ever surpassed the Saturn V in height, weight, or payload. If the two Russian Energia test launches are counted as operational, it had the same liftoff thrust as SA-513, 35.1 MN.

Hypothetical future versions of the Soviet Energia would have been significantly more powerful than the Saturn V, delivering 46 MN of thrust and able to deliver up to 175 metric tonnes to LEO in the "Vulkan" configuration. Planned uprated versions of the Saturn V using F-1A engines would have had about 18 percent more thrust and 137,250 kg (302,580 lb) payload. NASA contemplated building larger members of the Saturn family, such as the Saturn C-8, and also unrelated rockets, such as Nova, but these were never produced.

The Space Shuttle generates a peak thrust of 30.1 MN, and payload capacity to LEO (excl. Shuttle Orbiter itself) is 28,800 kg, which is about 25 percent of the Saturn V's payload. If the Shuttle Orbiter itself is counted as payload, this would be about 112,000 kg (248,000 lb). An equivalent comparison would be the Saturn V S-IVB third stage total orbital mass on Apollo 15, which was 140,976 kg (310,800 lb).

Some other recent launch vehicles have a small fraction of the Saturn V's payload capacity: the European Ariane 5 with the newest versions Ariane 5 ECA delivers up to 10,000 kg to geostationary transfer orbit (GTO). The US Delta 4 Heavy, which launched a dummy satellite on December 21, 2004, has a capacity of 13,100 kg to geosynchronous transfer orbit. The Atlas V rocket (using engines based on a Russian design) delivers up to 25,000 kg to LEO and 13,605 kg to GTO.

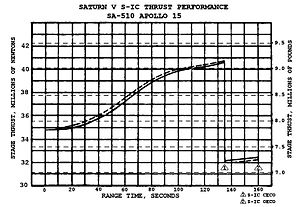

S-IC thrust comparisons

Because of its large size, attention is often focused on the S-IC thrust and how this compares to other large rockets. However, several factors make such comparisons more complex than first appears:

- Commonly-referenced thrust numbers are a specification, not an actual measurement. Individual stages and engines may fall short or exceed the specification, sometimes significantly.

- The F-1 thrust specification was uprated beginning with Apollo 15 (SA-510) from 1.5 million lbf (6.67 MN) to 1.522 million lbf (6.77 MN), or 7.61 million lbf (33.85 MN) for the S-IC stage. The higher thrust was achieved via a redesign of the injector orifices and a slightly higher propellant mass flow rate. However, comparing the specified number to the actual measured thrust of 7.823 million lbf (34.8 MN) on Apollo 15 shows a significant difference.

- There is no "bathroom scale" way to directly measure thrust of a rocket in flight. Rather a mathematical calculation is made from combustion chamber pressure, turbopump speed, calculated propellant density and flow rate, nozzle design, and atmospheric conditions, in particular, external pressure.

- Thrust varies greatly with external pressure and thus, with altitude, even for a non-throttled engine. For example on Apollo 15, the calculated total liftoff thrust (based on actual measurements) was about 7.823 million lbf (34.8 MN), which increased to 9.18 million lbf (40.8 MN) at T+135 seconds, just before centre engine cutoff (CECO), at which time the jet was heavily underexpanded.

- Thrust specifications are often given as vacuum thrust (for upper stages) or sea level thrust (for lower stages or boosters), sometimes without qualifying which one. This can lead to incorrect comparisons.

- Thrust specifications are often given as average thrust or peak thrust, sometimes without qualifying which one. Even for a non-throttled engine at a fixed altitude, thrust can often vary somewhat over the firing period due to several factors. These include intentional or unintentional mixture ratio changes, slight propellant density changes over the firing period, and variations in turbopump, nozzle and injector performance over the firing period.

Without knowing the exact measurement technique and mathematical method used to determine thrust for each different rocket, comparisons are often inexact. As the above shows, the specified thrust often differs significantly from actual flight thrust calculated from direct measurements. The thrust stated in various references is often not adequately qualified as to vacuum vs sea level, or peak vs average thrust.

Similarly, payload increases are often achieved in later missions independent of engine thrust. This is by weight reduction or trajectory reshaping.

The result is there is no single absolute figure for engine thrust, stage thrust or vehicle payload. There are specified values and actual flight values, and various ways of measuring and deriving those actual flight values.

The performance of each Saturn V launch was extensively analyzed and a Launch Evaluation Report produced for each mission, including a thrust/time graph for each vehicle stage on each mission.

Assembly

After the construction of a stage was completed, it was shipped to the Kennedy Space Centre. The first two stages were so large that the only way to transport them was by barge. The S-IC constructed in New Orleans was transported down the Mississippi River to the Gulf of Mexico. After rounding Florida, it was then transported up the Intra-Coastal Waterway to the Vertical Assembly Building (now called the Vehicle Assembly Building). The S-II was constructed in California and so traveled via the Panama Canal. The third stage and Instrument Unit could be carried by the Aero Spacelines Pregnant Guppy and Super Guppy.

On arrival at Vertical Assembly Building, each stage was checked out in a horizontal position before being moved to a vertical position. NASA also constructed large spool-shaped structures that could be used in place of stages if a particular stage was late. These spools had the same height and mass and contained the same electrical connections as the actual stages.

NASA decided to use a mobile launch tower, or " crawler", built by Marion Power Shovel of Ohio. This meant that the rocket was constructed on the launch pad in the VAB and then the whole structure was moved out to the launch site by the crawler, which is still used today by the Space Shuttle program. It runs on four double tracked treads, each with 57 'shoes'. Each shoe weighs 900 kg (2,000 lb). This transporter had to keep the rocket level as it traveled the 3 miles (5 km) to the launch site.

Lunar mission launch sequence

The Saturn V carried the Apollo astronauts to the Moon. All Saturn V missions launched from Launch Complex 39 at the John F. Kennedy Space Centre. After the rocket cleared the launch tower, mission control transferred to the Johnson Space Centre in Houston, Texas.

An average mission used the rocket for a total of just 20 minutes. Although Apollo 6 and Apollo 13 experienced engine failures, the onboard computers were able to compensate by burning the remaining engines longer, and none of the Apollo launches resulted in a payload loss.

S-IC sequence

The first stage burned for 2.5 minutes, lifting the rocket to an altitude of 42 miles (68 kilometers) and a speed of 6164 mph (9921 km/h) and burning 2,000,000 kg of propellant.

At 8.9 seconds before launch, the first stage ignition sequence started. The centre engine ignited first, followed by opposing outboard pairs at 300-millisecond stagger times to reduce the structural loads on the rocket. The moment full thrust had been confirmed by the onboard computers, the rocket was 'soft-released' in two stages: first, the hold-down arms released the rocket, and second, as the rocket began to accelerate upwards, it was held back somewhat by tapered metal pins being pulled through holes. The latter lasted for half a second. Once the rocket had lifted off, it could not safely settle back down onto the pad if the engines failed.

It took about 12 seconds for the rocket to clear the tower. As it moved past the tower, the rocket yawed away to ensure adequate clearance in case of adverse winds. At an altitude of 430 ft (130 meters) the rocket began to roll and then pitch to the correct azimuth. From launch until 38 seconds after second stage ignition, the Saturn V would fly a preprogrammed pitch program biased for the prevailing winds during the launch month. The four outboard engines also tilted away from the centre, so that if one engine had shut down early, the thrust of the remaining engines would have been towards the rocket's centre of gravity. The Saturn V quickly accelerated, reaching 1600 feet/s. (500 m/s) at 1+ miles (2 km) in altitude. Much of the early portion of the flight was spent gaining altitude, with the required velocity coming later.

At about 80 seconds, the rocket reached the point of the flight with the maximum dynamic pressure, known as Max Q. The dynamic pressure on a rocket varies jointly as the air density around the rocket and the square of the speed. Although the speed is increasing as the rocket gets higher, the air density beyond Max Q is decreasing so rapidly that the dynamic pressure is effectively reduced.

At 135.5 seconds, the centre engine would shut down to reduce the acceleration loads on the rocket, since it became lighter as fuel was used. The F-1 engine could not throttle down so this was the easiest method. The crew also experienced their greatest acceleration, 4 g (129 ft/s²; 39 m/s²), just before first stage cut off. The other engines continued to burn until either the oxidizer or fuel was depleted as measured by sensors in the suction assemblies. The first stage separated 600 milliseconds after the engine cutoff. This was done with the help of the eight small solid fuel separation motors and occurred at an altitude of about 38 miles (62 km). The first stage continued to an altitude of 68 miles (110 km), then fell in the Atlantic Ocean about 350 miles (560 km) from the launch pad.

S-II sequence

After the S-IC sequence, the S-II second stage burned for 6 minutes and propelled the craft to 109 miles (176 km) and 15,647 mph (25,182 km/hr -- 7.00 km/s), bringing it close to orbital velocity.

The second stage had a two-part ignition process, which varied over the duration of the program. In the first part for the first two unmanned launches, eight solid-fuel ullage motors ignited for four seconds to give positive acceleration, followed by the five J-2 engines. For the first seven manned Apollo missions only four ullage motors were used, and they were eliminated completely for the final four launches. In the second part, about 30 seconds after the first stage separated, the aft interstage separated from the second stage. This was a precisely controlled maneuver as the interstage could not be allowed to touch the engines and had a clearance of only one meter. At the same time as the interstage separated, the Launch Escape System was jettisoned. See Apollo abort modes for more information about the various abort modes that could have been used during a launch.

About 38 seconds after the second stage ignition the control guidance of the Saturn V switched from a preprogrammed pitch routine to Iterative Guidance Mode, controlled by the Instrument Unit, based on accelerometers and altitude sensors. If the Instrument Unit took the rocket outside allowed limits the crew could either abort or take control of the rocket using one of the rotational hand controllers in the capsule.

About 90 seconds before the second stage cutoff, the centre engine shut down to reduce longitudinal pogo oscillations. A pogo suppressor, first flown on Apollo 14, stopped this motion but the centre engine was still shut down early to limit acceleration G forces. At around this time, the LOX flow rate decreased, changing the mix ratio of the two propellants, ensuring that there would be as little propellant as possible left in the tanks at the end of second stage flight. This was done at a predetermined delta-v.

There were five sensors in the bottom of each tank of the S-II. When two of these were uncovered, the Instrument Unit would initiate the staging sequence. One second after the second stage cut off it separated and a tenth of a second later the third stage ignited. Solid fuel retro-rockets mounted on the interstage at the top of the stage fired to help back away the depleted second stage from the remainder of the stack. The S-II impacted about 4200 km from the launch site.

S-IVB sequence

The third stage burned for a further 2.5 minutes, boosting speed to 17,450 mph (28,083 km/hr), about 12 minutes after launch. For missions other than low Earth orbit, the third stage remained attached while the spacecraft orbited the Earth two and a half times in a parking orbit while astronauts and mission controllers examined the spacecraft and rocket to make sure everything functioned nominally.

Unlike the previous separation, there was no two-stage separation. The interstage between the second and third stages remained attached to the second stage (although it was constructed as part of the third stage).

By 10 minutes 30 seconds into the launch, the Saturn V was 164 km in altitude and 1700 km downrange from the launch site. After about five more minutes of burning, the rocket cut off. In the early Apollo missions, the spacecraft was put into a temporary "parking orbit" of about 180 km by 165 km. This is quite low by Earth orbit standards and would not have remained stable for very long due to interaction between the spacecraft and the Earth's atmosphere. For the final three Apollo flights, the temporary parking orbit was even lower (approximately 150 km), to allow greater lunar payload capacity for these missions. For the two Earth orbit missions of the Saturn V, Apollo 9 and Skylab, the orbits were higher, more typical of manned orbital missions. The next two and a half orbits were spent checking out the systems of the spacecraft and preparing the spacecraft for Trans Lunar Injection (TLI).

TLI came about two and a half hours after launch, when the third stage reignited to propel the spacecraft to the Moon. The S-IVB burned for almost six minutes so that the total spacecraft velocity at cutoff was close to the 11.2 km/s (40,320 km/hr; 25,053 mph) escape velocity. This resulted in an energy-efficient transfer such that moon's gravity would help to arrive at the target, also resulting in lower fuel consumption for the moon orbit insertion.

A couple of hours after TLI the Apollo Command Service Module (CSM) separated from the third stage, turned 180 degrees, and docked with the Lunar Module (LM) which rode below the CSM during launch. The CSM and LM then separated from the third stage.

If it were to remain on the same trajectory as the spacecraft, the booster could have presented a hazard later in the mission, so the remaining propellant in its tanks was vented out of the engine, changing its trajectory. For third stages from Apollo 13 onwards, controllers directed it to impact the Moon. Seismometers left behind by previous missions detected the impacts, and the information helped map the inside of the Moon. Before that, the stages (except Apollo 9) were directed towards a flyby of the Moon designed to use lunar gravity as a gravitational slingshot into solar orbits. Apollo 9's S-IVB was put directly into a solar orbit.

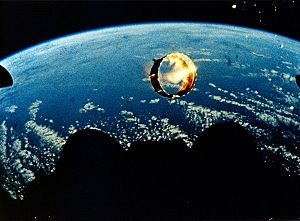

On September 3, 2002, Bill Yeung discovered a suspected asteroid, which was given the discovery designation J002E3. It appeared to be in orbit around the Earth, and was soon discovered from spectral analysis to be covered in white titanium dioxide paint, the same paint used for the Saturn V. Calculation of orbital parameters identified the apparent asteroid as being the Apollo 12 S-IVB stage. Mission controllers had planned to send Apollo 12's S-IVB into solar orbit, but the burn after separating from the Apollo spacecraft lasted too long, and hence it did not pass close enough to the Moon, remaining in a barely-stable orbit around the Earth and Moon. In 1971, through a series of gravitational perturbations, it is believed to have entered in a solar orbit and then returned into weakly-captured Earth orbit 31 years later. It left Earth orbit again in June 2003.

Skylab

In 1968, the Apollo Applications Program was created to look into science missions that could be performed with the surplus Apollo hardware. Much of the planning centered on the idea of a space station, which eventually spawned the Skylab program. Skylab was launched using a two-stage Saturn V, sometimes called a Saturn INT-21,. It was the only launch not directly related to the Apollo lunar landing program.

Originally it was planned to use a ' wet workshop' concept, with a rocket stage being launched into orbit by a Saturn 1B and its spent S-IVB outfitted in space, but this was abandoned for the ' dry workshop' concept: An S-IVB stage from a Saturn IB was converted into a space station on the ground and launched on a Saturn V. A backup, constructed from a Saturn V third stage, is now on display at the National Air and Space Museum.

Three crews lived aboard Skylab from May 25, 1973 to February 8, 1974, with Skylab remaining in orbit until July 11, 1979.

It was originally hoped that Skylab would stay in orbit long enough to be visited by the Space Shuttle during its first few flights. The Shuttle could have raised Skylab's orbit, and allowed it to be used as a base for future space stations. However, the Shuttle did not fly until 1981, and it is now realized in retrospect that Skylab would have been of little use, as it was not designed to be refurbished and replenished with supplies.

Proposed post-Apollo developments

The (cancelled) second production run of Saturn Vs would very likely have used the F-1A engine in its first stage, providing a substantial performance boost. Other likely changes would have been the removal of the fins (which turned out to provide little benefit when compared to their weight); a stretched S-IC first stage to support the more powerful F-1As; and uprated J-2s for the upper stages.

A number of alternate Saturn vehicles were proposed based on the Saturn V, ranging from the Saturn INT-20 with an S-IVB stage and interstage mounted directly onto an S-IC stage, through to the Saturn V-23(L) which would not only have five F-1 engines in the first stage, but also four strap-on boosters with two F-1 engines each: giving a total of thirteen F-1 engines firing at launch.

The Space Shuttle was initially conceived of as a cargo transport to be used in concert with the Saturn V, even to the point that a " Saturn-Shuttle," using the current orbiter and external tank, but with the tank mounted on a modified, fly-back version of the S-IC, would be used to power the Shuttle during the first two minutes of flight, after which the S-IC would be jettisoned (which would then fly back to KSC for refurbishment) and the Space Shuttle Main Engines would then fire and place the orbiter into orbit. The Shuttle would handle space station logistics, while Saturn V would launch components. Lack of a second Saturn V production run killed this plan and has left the United States without a heavy-lift booster. Some in the U.S. space community have come to lament this situation, as continued production would have allowed the International Space Station, using a Skylab or Mir configuration with both U.S. and Russian docking ports, to have been lifted with just a handful of launches, with the "Saturn Shuttle" concept possibly eliminating the conditions that caused the Challenger Disaster in 1986.

The Saturn V would have been the prime launch vehicle for the canceled Voyager Mars probes, and was to have been the launch vehicle for the nuclear rocket stage RIFT test program and the later NERVA.

Successors

U.S. proposals for a rocket larger than the Saturn V from the late 1950s through the early 1980s were generally called Nova. Over thirty different large rocket proposals carried the Nova name.

Wernher von Braun and others also had plans for a rocket that would have featured eight F-1 engines in its first stage allowing it to launch a manned spacecraft on a direct ascent flight to the Moon. Other plans for the Saturn V called for using a Centaur as an upper stage or adding strap-on boosters. These enhancements would have increased its ability to send large unmanned spacecraft to the outer planets or manned spacecraft to Mars.

As of 2006, NASA plans to build the heavy-lift Ares V, a Shuttle Derived Launch Vehicle only 5 feet shorter than the Saturn V, but can lift the same amount of weight (~125 to 130 T) as its predecessor. The launcher has been named as a homage to the Saturn V. It is intended as an unmanned heavy lift vehicle, like that of the Saturn INT-21/Skylab configuration, but unlike the Saturn INT-21, the Ares V will be used to support both future manned lunar landings and even future manned missions to Mars by 2030.

The Saturn V used three liquid-fueled stages, the first burning liquid oxygen and kerosene, and the upper two burning liquid hydrogen and oxygen. By contrast the Ares V will use two liquid-fueled hydrogen/oxygen stages, and for the first two minutes of powered flight, two modified Space Shuttle Solid Rocket Boosters. The core stage will be powered by five modified RS-68 rocket engines in the same cross pattern as that used on the S-IC and S-II stages. Initial Ares V design used five Space Shuttle Main Engines, but the RS-68 was later adopted based on lower costs, and its successful flight use on the unmanned Delta IV EELV launch system, along with being more powerful and easier to construct than its SSME counterpart.

The RS-68 engines, built by the Rocketdyne Division of Pratt and Whitney (formerly under the ownerships of Boeing and Rockwell International) produce less than half the thrust per engine as the Saturn V's F-1 engines, but are more efficient and can be throttled up or down. The J-2 engine used on the S-II and S-IVB will be modified into the improved J-2X engine for use on the Earth Departure Stage (EDS), and on the second stage of the proposed Ares I. Both the EDS and the Ares I second stage would use a single J-2X motor, although the EDS was originally designed to use two motors until the redesign employing the five RS-68s in place of the five SSMEs.

Cost

From 1964 until 1973, a total of US$6.5 billion was appropriated for the Saturn V, with the maximum being in 1966 with US$1.2 billion. Allowing for inflation this is equivalent to roughly $32-45 billion in 2007 money. This works out at an amortised cost of $2.4-3.5 billion per launch.

One of the main reasons for the cancellation of the Apollo program was the cost. In 1966, NASA received its highest budget of US$4.5 billion, about 0.5 percent of the GDP of the United States at that time.

Saturn V vehicles and launches

| Serial Number | Mission | Launch Date | Notes |

|---|---|---|---|

| SA-501 | Apollo 4 | November 9, 1967 | First test flight, a complete success. |

| SA-502 | Apollo 6 | April 4, 1968 | Second test flight, with some serious second and third stage problems occurring. |

| SA-503 | Apollo 8 | December 21, 1968 | First manned flight of Saturn V and lunar orbit |

| SA-504 | Apollo 9 | March 3, 1969 | Earth orbit LM test |

| SA-505 | Apollo 10 | May 18, 1969 | Lunar orbit LM test |

| SA-506 | Apollo 11 | July 16, 1969 | First manned lunar landing |

| SA-507 | Apollo 12 | November 14, 1969 | Landed near Surveyor 3. Vehicle was struck twice by lightning after liftoff with no serious damage. |

| SA-508 | Apollo 13 | April 11, 1970 | Mission aborted en route to moon, crew saved. |

| SA-509 | Apollo 14 | January 31, 1971 | Landed near Fra Mauro |

| SA-510 | Apollo 15 | July 26, 1971 | First Lunar Rover |

| SA-511 | Apollo 16 | April 16, 1972 | Landed at Descartes |

| SA-512 | Apollo 17 | December 6, 1972 | First and only night launch; Final Apollo lunar mission |

| SA-513 | Skylab 1 | May 14, 1973 | Two-stage Skylab version ( Saturn INT-21) |

| SA-514 | Unused | Designated but never used for Apollo 18/19 | |

| SA-515 | Unused | Designated but never used as a backup Skylab launch vehicle | |

Currently there are three Saturn Vs on display:

- At the Johnson Space Centre made up of first stage of SA-514, the second stage from SA-515 and the third stage from SA-513.

- At the Kennedy Space Centre made up of S-IC-T (test stage) and the second and third stages from SA-514.

- At the U.S. Space & Rocket Center, made up of S-IC-D, S-II-F/D and S-IVB-D (all test stages not meant for actual flight) (displayed in the Davidson Centre for Space Exploration).

Of these three, only the one at the Johnson Space Centre consists entirely of stages meant to be launched. The U.S. Space & Rocket Centre in Huntsville also has on display an erect full scale model of the Saturn V. Additionally, the S-IC stage from SA-515 resides on display at the Michoud Assembly Facility in New Orleans, Louisiana. The S-IVB stage from SA-515 was converted for use as a backup for Skylab. The Skylab backup is now on display at the National Air and Space Museum in Washington, D.C..

The blueprints or other plans for the Saturn V still exist on microfilm at the Marshall Space Flight Centre.