Recycling of used lead acid batteries

Practical Action

Generally there are two types of Lead-acid storage batteries, based on their method of

construction: flooded or sealed. Flooded (or wet) lead acid batteries are those where the

electrodes/plates are immersed in electrolyte and regular refilling with water is necessary to

safeguard proper activity. In a sealed lead acid or valve-regulated Lead acid (VRLA) battery

the electrolyte is immobilized. All lead acid batteries produce hydrogen and oxygen gas

(gassing) at the electrodes during charging through a process called electrolysis. These gases

are allowed to escape a flooded cell, however the sealed cell is constructed so that the gases

are contained and recombined.

The grid structure in both batteries is made from a lead alloy. A pure lead grid structure is

not strong enough and therefore other metals like antimony, calcium, tin, and selenium in

small quantities are alloyed for added strength and improved electrical properties.

Lifetime

The battery lifetime is defined as the period of time in which a battery is capable of being

recharged and retain the charge applied. Once the battery is no longer capable of being

recharged or cannot retain its charge properly, its lifetime reaches its end and it becomes a

`used battery` for the application it was designed for (UNEP, 2003).

The lifetime of a lead acid battery is very dependent on its rate, conditions and kind of use. It

is estimated to be between 1 up to 5 years.

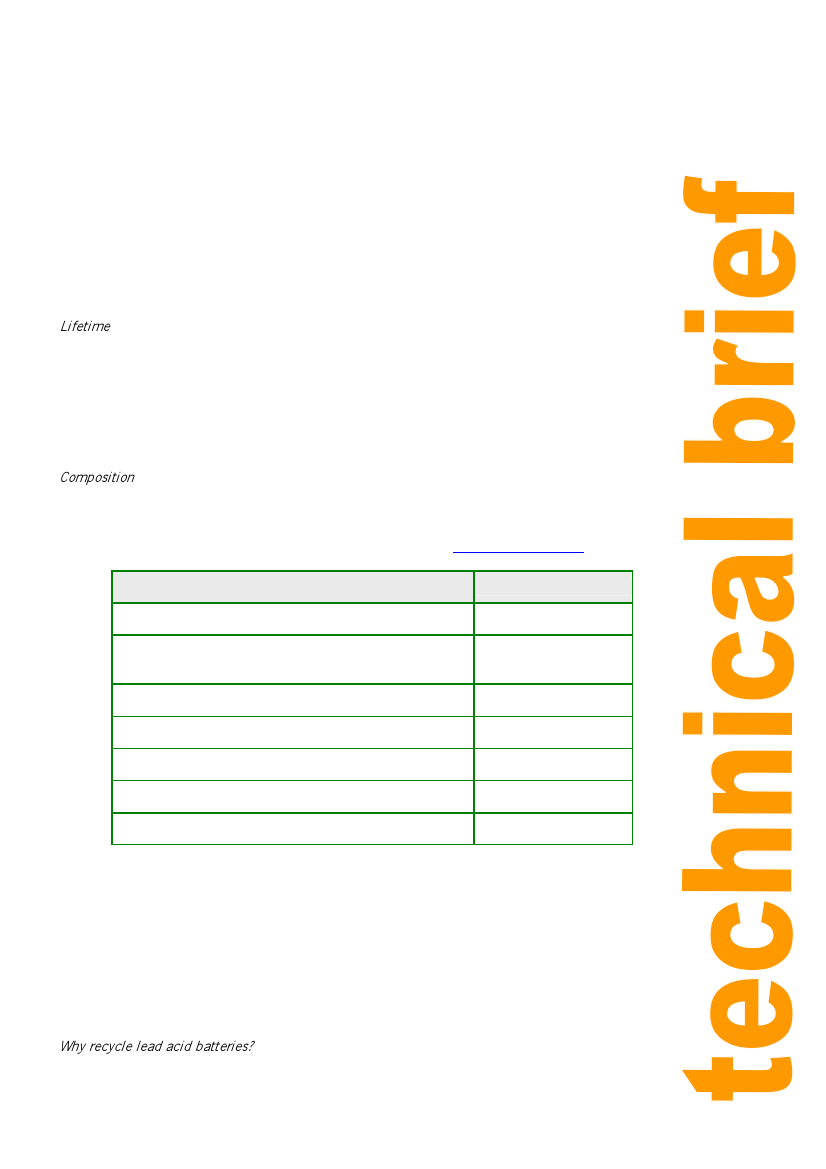

Composition

The typical lead acid battery comprises of: metal grids, electrode paste, Sulphuric acid,

connectors and poles of lead alloy, and grid separators made up of PVC (see table 1). The

battery components are contained in a corrosion and heat-resistant housing usually composed

of plastic (polycarbonate, polypropylene, or polystyrene) (source: www.gravitaexim.com).

Component

Lead (alloy) components (grid, poles)

Electrode paste (fine particles of Lead oxide and Lead

sulphate)

Sulphuric acid (10 - 20 % H2SO4)

Polypropylene

Other plastics (PVC, PE, etc.)

Ebonite

Others materials (glass, etc.)

[wt.-%]

25 - 30

35 - 45

10 - 15

5-8

4-7

1-3

< 0.5

Table 1: Composition of typical lead acid battery scrap

Recycling

Returning used lead acid batteries to the recycling loop has a long tradition. Thanks to the

compactness of the battery, its high lead proportion and relatively high metal prices, it has

been worthwhile for consumers to return their own or collected car batteries to the scrap trade

or secondary smelters. This is also the case in low-income countries and return rates of up to

80% can be achieved normally through an informal collection system of scrap dealers,

secondary lead processors and consumers (Vest, 2002).

Why recycle lead acid batteries?

The benefits of recycling of lead acid batteries are numerous. Unless we recycle used

batteries certain toxic components pose a potential risk to the environment and human

health. Moreover recovering scrap batteries has the advantages that it is easier and much less

2