Biogas

Practical Action

Household-level technologies

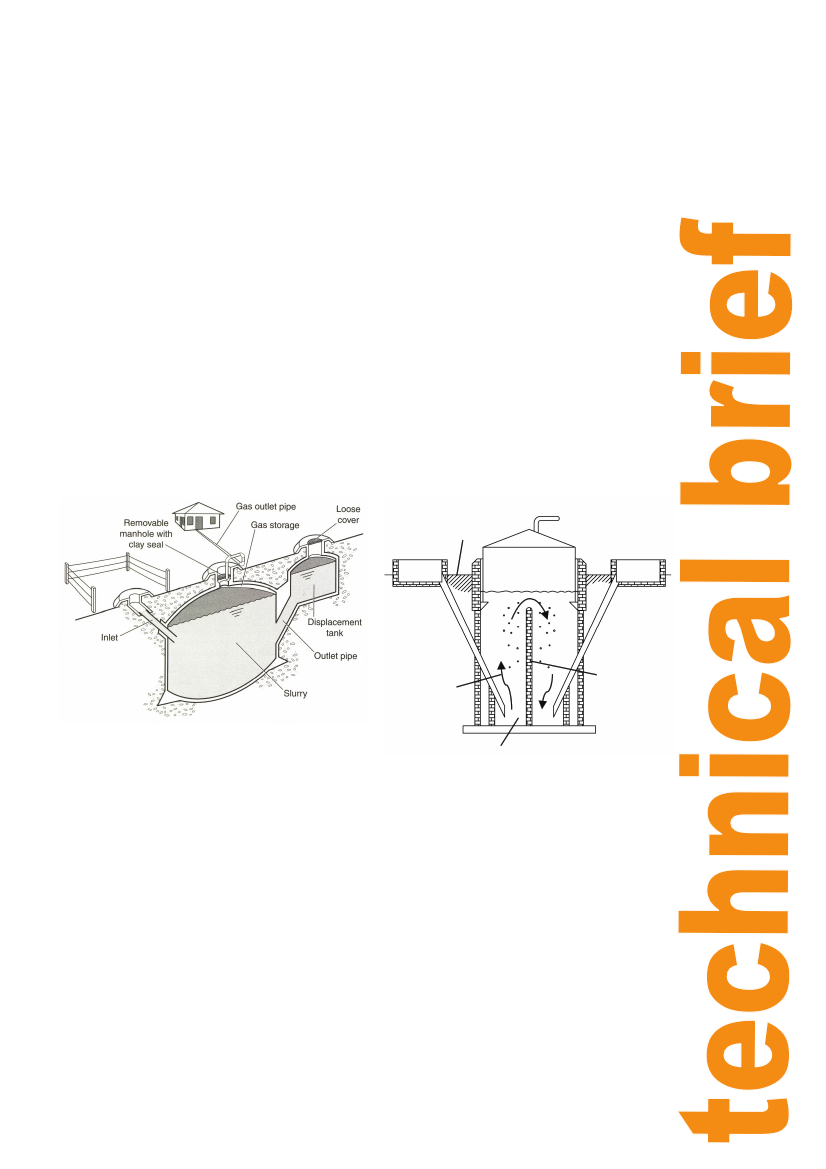

The most widespread designs of digester are the Chinese fixed dome digester and the Indian

floating cover biogas digester (shown in figures 1& 2). The digestion process is the same in each

digester but the gas collection method is different. In the floating cover type, the water sealed

cover of the digester is capable of rising as gas is produced, where it acts as a storage chamber,

whereas the fixed dome type has a lower gas storage capacity and requires good sealing if gas

leakage is to be prevented. Both have been designed for use with animal waste or dung.

The waste is fed into the digester via the inlet pipe and undergoes digestion in the digestion

chamber. The temperature of the process is quite critical - methane producing bacteria operate

most efficiently at temperatures between 30 - 40°C or 50 - 60°C - and in colder climates heat

may have to be added to the chamber to encourage the bacteria to carry out their function. The

product is a combination of methane and carbon dioxide, typically in the ratio of 6:4. Digestion

time ranges from a couple of weeks to a couple of months depending on the feedstock and the

digestion temperature. The residual slurry is removed at the outlet and can be used as a fertiliser.

From a household perspective, the gas should always be available, so those digesters which

allow continuous addition of feedstock which displaces spent feedstock is likely to be the

most appropriate and acceptable. Batch systems, which require the physical removal of slurry

every few days and the addition of new feedstock are both labour intensive and disruptive to

supply.

Inlet

Ground

level

Gas outlet

Outlet

Gas

Direction

of flow

Partition

wall

Figure 1: Fixed dome digester

Slurry

Figure 2: Floating cover digester

Biogas digesters where water is a constraint

This digester, developed by the Central Institute of Agricultural Engineering, Bhopal, India, is a

modification of the fixed-dome type and it allows fresh undiluted cattle dung to be used. The

modified design requires very little or no water for mixing with the cattle dung, generates about

50% more biogas for each kilogram of dung loaded into the system, and does not require slurry

drying time before it can be used as fertiliser.

The main changes to a conventional fixed dome digester are an increase in the bore of the inlet

feed, greater reinforcement of the chamber to withstand the higher gas pressures, an enlarged

slurry chamber outlet and a smooth widened outlet channel to streamline the flow of the slurry

(Shyam, 2001).

3